12 Stress Transformation

The preceding chapters discussed how to calculate normal and shear stresses that arise from various loading situations. Also discussed was how those stresses can vary from point to point on a body or structure. The combination of normal stress and shear stress that exists at a point is referred to as the general stress state. When we restrict analysis to 2D states of stress, we can represent the stress state on a 2D stress element as discussed in Section 4.7 and illustrated in Figure 4.9 for the x-y plane.

The plane of the stress state depends on the coordinate system chosen for calculating the stresses. The coordinate system most often chosen is one considered to be the most straightforward system for the given loading directions and geometrical orientation of the body. However, the plane for which the stresses are most easily calculated is not always the only plane for which we would want to know the stress state.

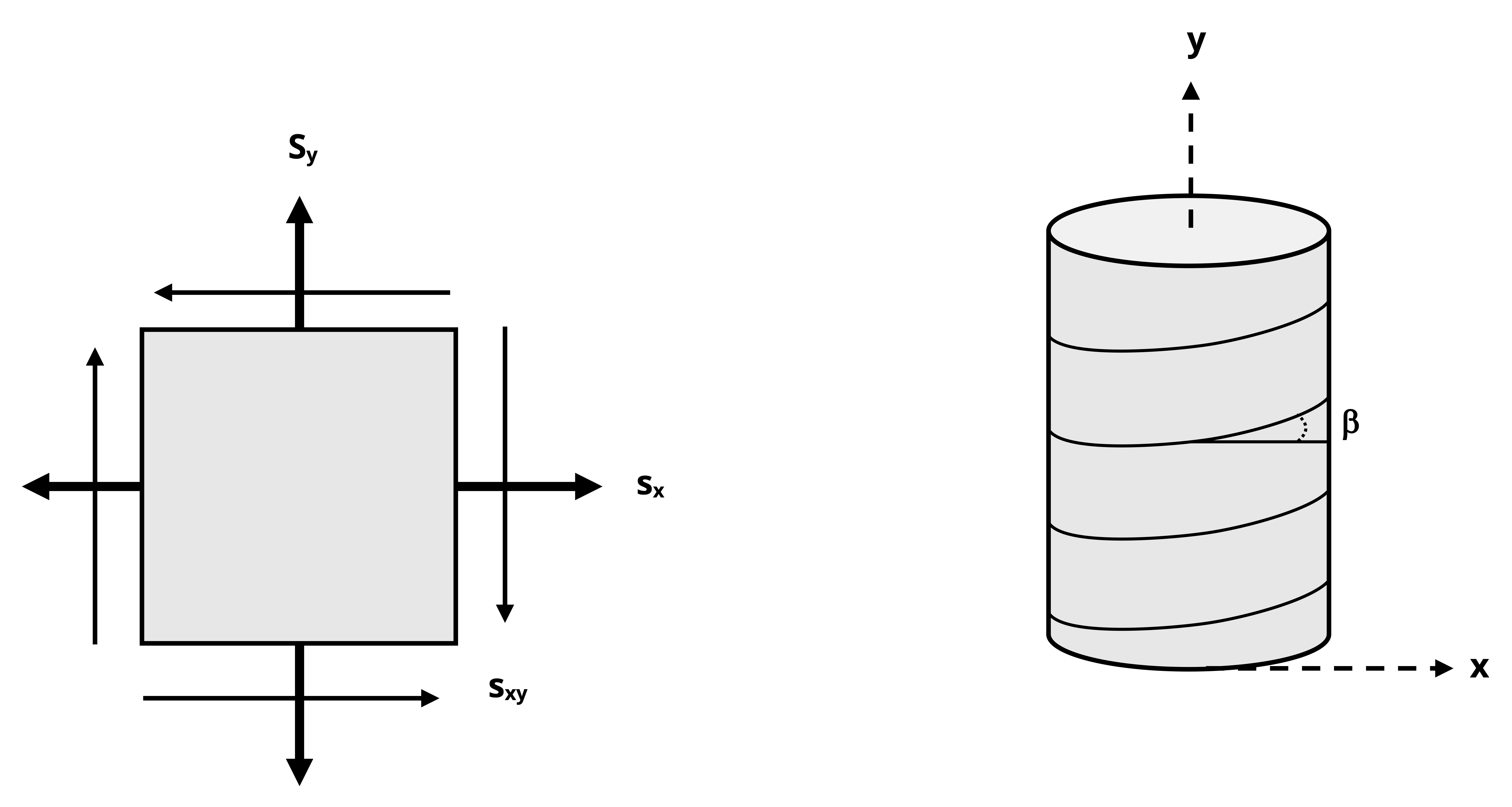

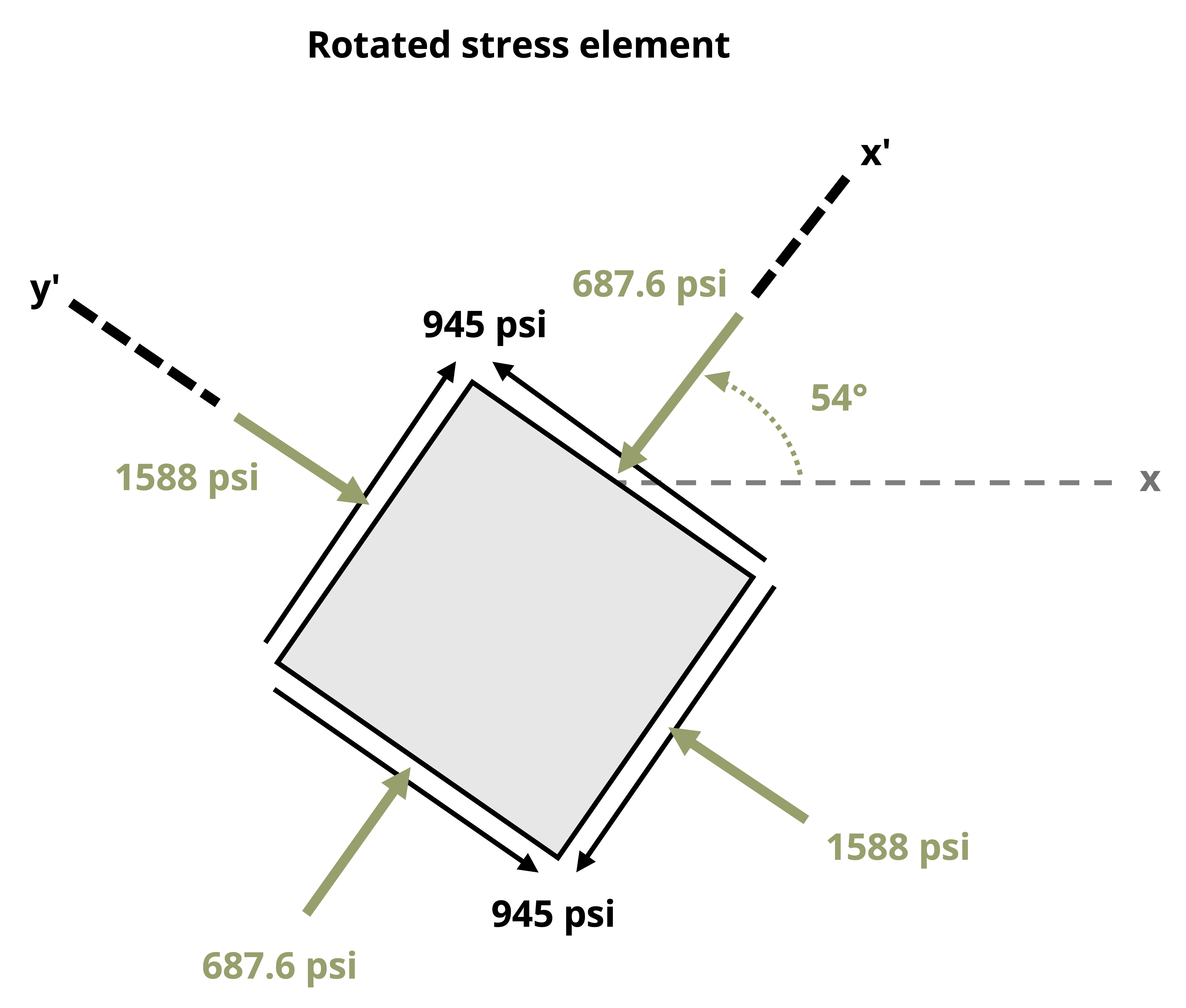

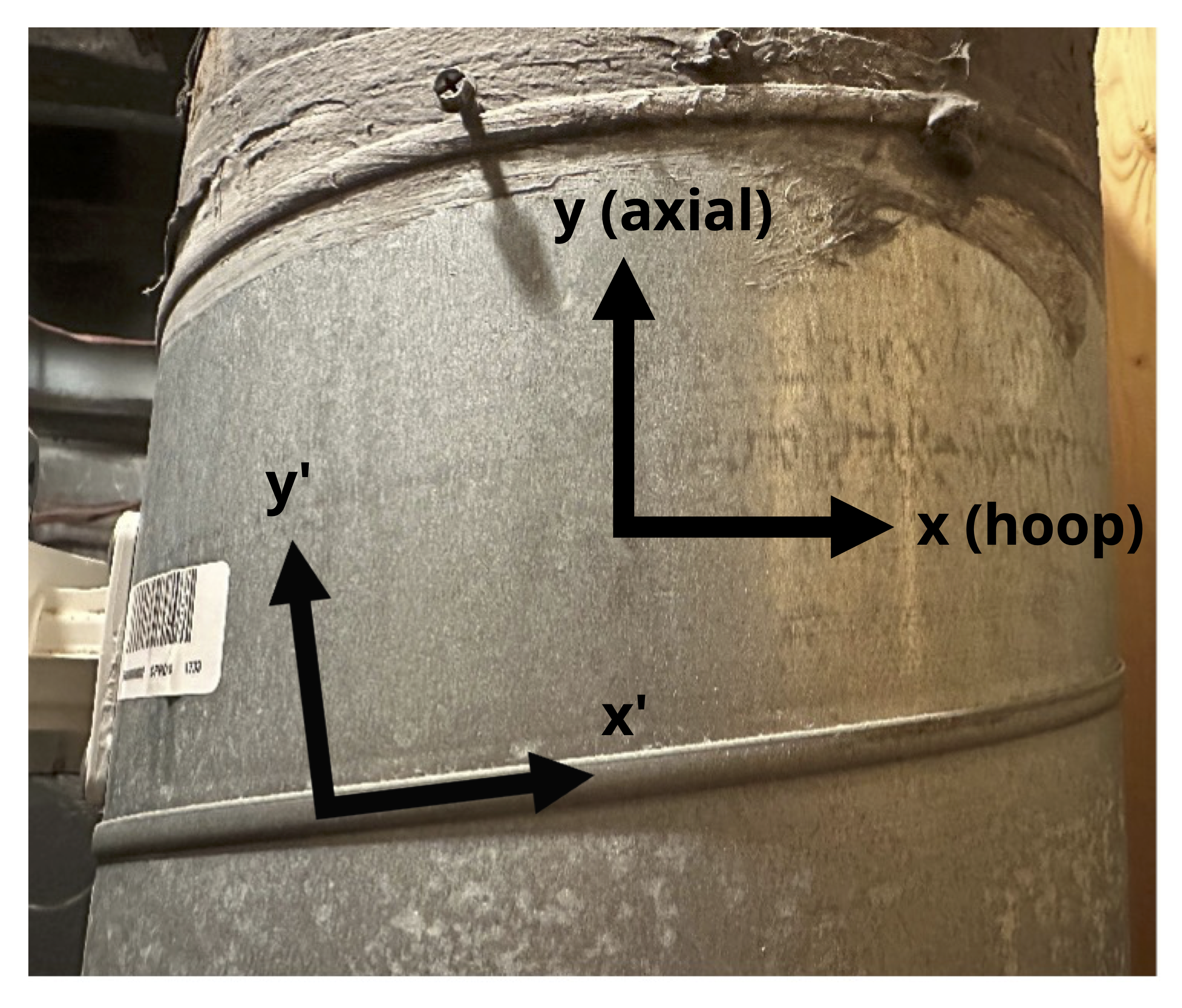

For example, Figure 12.1 shows an air duct that is part of a heat pump system and is subject to internal air pressure. The welded seams are wound in a helical pattern that forms an angle with the horizontal (x) axis. Chapter 13 develops basic equations to calculate stress in the x-y plane due to pressure. However, in this case it’s additionally important to know the stresses in the directions parallel and perpendicular to the weld seams (x’-y’ plane) to ensure that the weld could tolerate the loading, so being able to transform the stresses we can most easily calculate in x and y directions to the x’ and y’ directions would be useful.

This chapter begins by detailing how to represent a 2D stress state on a stress element (Section 12.1).

Then it addresses how to derive stress transformation equations that allow us to use a given stress state in one plane to find the corresponding stress state in different planes (Section 12.2). This process is known as stress transformation.

Also addressed is how to derive equations that allow us to determine the planes on which the maximum and minimum normal and shear stresses occur and the corresponding stress states (Section 12.3). The maximum and minimum normal stresses are considered principal stresses.

Section 12.4 discusses an alternative graphical method for performing stress transformation, known as Mohr’s circle.

Section 12.5 prompts us to use Mohr’s circle to expand our analysis and look not only at the shear stress in the original 2D plane but also out-of-plane shear stress.

12.1 Stress Elements for 2D Stress States

Click to expand

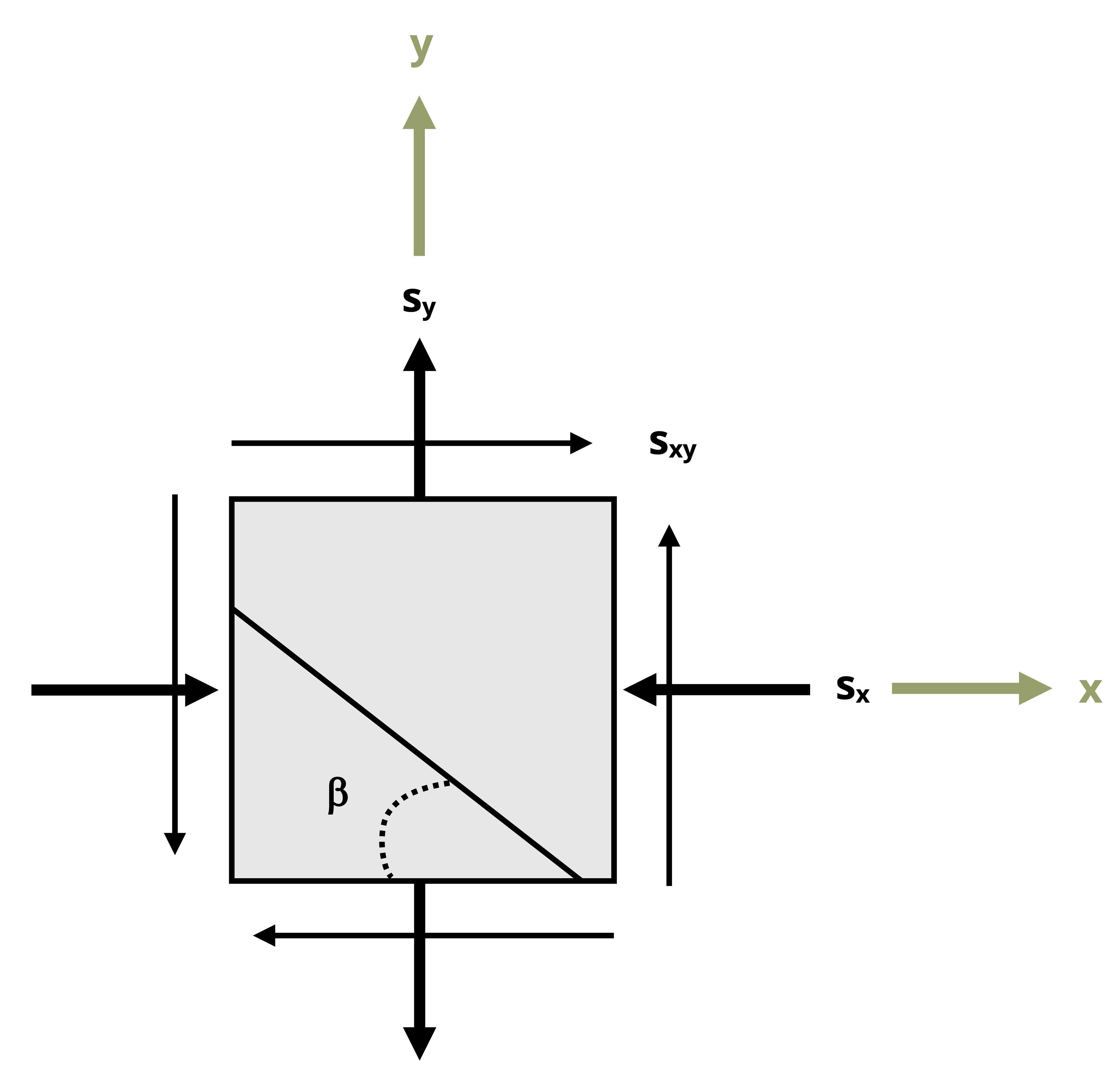

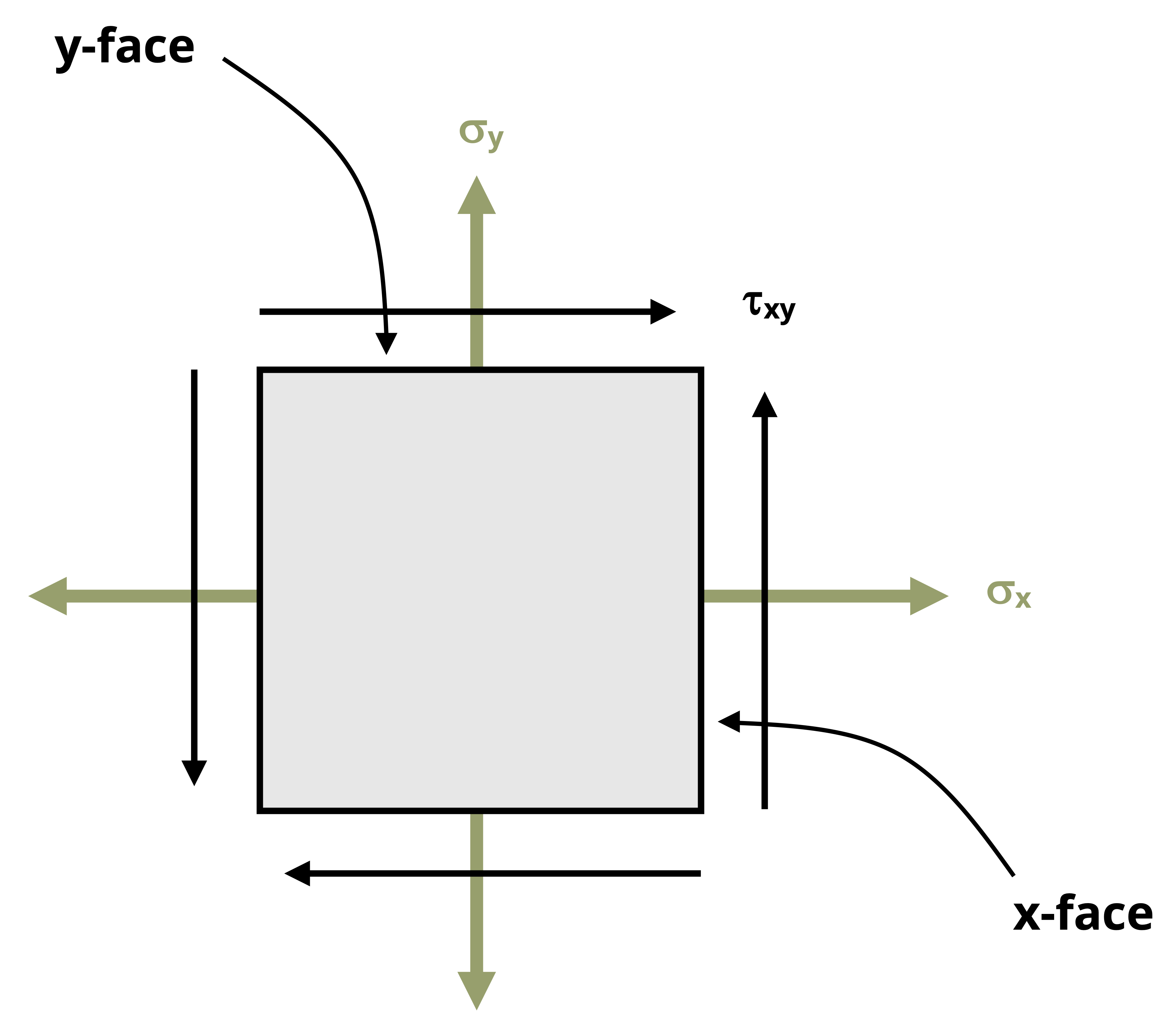

A square stress element shows the normal stress and shear stress at a point for a 2D stress state (see Figure 12.4). Here we discuss the important aspects of the stress element:

1. Plane of the element

The coordinate axes on the stress element represent the plane on the body where the point is located, with the positive directions indicated by arrows and axes labels. To determine the plane a point is on, we observe the axes on a square element on the side of the body when viewing it straight on. Figure 12.2 illustrates three points on a body, each on a different plane (x-y, y-z, and x-z).

2. Positive and negative faces

We refer to the edges of the element as positive faces and negative faces depending on which way the coordinate axes are oriented. For example, if the vertical coordinate axis is positive upward, then the top edge of the element is the positive face for that coordinate axis and the bottom edge is the negative face. This is illustrated for two different planes in Figure 12.3.

3. Normal stresses

Normal stresses that are positive (tensile) are illustrated by arrows that point away from the element. Negative normal stresses (compressive) point toward the element. Normal stresses directed in the horizontal direction are shown on the left and right faces of the element, and normal stresses directed in the vertical direction are shown on the top and bottom faces.

4. Shear stress

As explained in Section 4.7, the shear stress will be the same on all sides of the stress element. The manner in which the shear stress arrows are oriented around the body indicates the sign. A positive shear stress is one for which the shear stress arrow points in a positive direction on a positive face or in a negative direction on a negative face. The arrows are drawn such that no matter which face you choose to examine, you should reach the same conclusion. The magnitude of the shear stress is usually specified in one corner of the element.

For example, Figure 12.3 shows that for the positive shear stress case, the shear stress arrow on the +x-face points in the +y direction and the shear stress arrow on the -x-face points in the -y direction. Either way a positive shear stress is indicated and would yield the same result as for the y-faces.

For the negative shear stress case, the shear stress arrow on the +x-face points in the -z direction and the shear stress arrow on the -x-face points in the +z direction. Either way a negative shear stress is indicated and would yield the same result as for the z-faces.

An example of a fully drawn stress element can be found in Figure 12.4. In this case the shear stress is 𝜏xz = +16 MPa (note the positive z-directed shear stress arrow on the positive x-face), and the normal stresses are 𝜎x = -150 MPa and 𝜎z = +90 MPa.

12.2 Stress Transformation Equations

Click to expand

The Section 12.2.1 stress transformation equations allow us to use a set of stresses in one given plane (e.g., σx, σy, and τxy) as inputs to determine stresses in any other plane of interest. Understanding the derivations will help lend clarity to the inputs and outputs of the equations. If you wish to skip the derivation, go directly to Equation 12.1 and/or Equation 12.2. Section 12.2.2 covers the details of how to use the equations.

12.2.1 Derivation of Equations

Transformation of a uniaxial stress state was examined in Section 2.4. In that case a known force acting in the axial direction enabled us to determine the stress on an inclined plane. The current derivation for a more general stress state is based on the same idea of cutting a section and applying equilibrium.

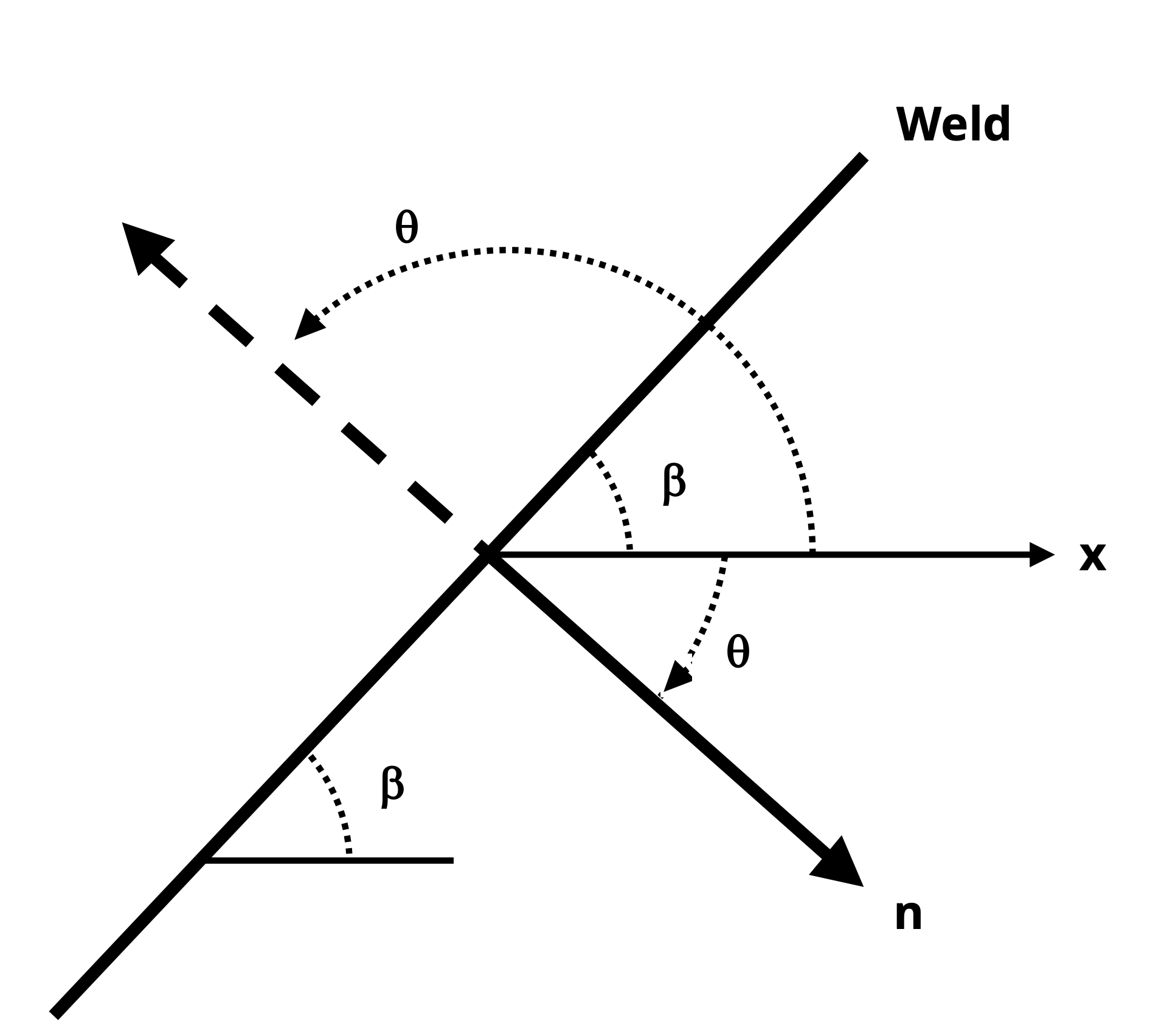

Figure 12.5 shows a stress element representing a general stress state in the x-y plane and the full body diagram (FBD)—but with stresses instead of forces—of the element cut along the plane of interest. The n and t directions are normal and parallel to the incline respectively, and 𝜃 and 𝛽 are complementary angles.

We can proceed as follows:

1. Write expressions for the forces that correspond to the stresses acting on the cut element. Do this by multiplying the stresses with the area of the side of the element they act on. These areas are illustrated in Figure 12.5 (C). Note that σy and the τxy on the bottom face of the element act on area dAy, while σx and the τxy on the left face of the element act on area dAx. The internal forces normal and parallel to the incline act on area dA’.

On the left face we have

\[ F_x=-\sigma_x\ dA_x\\ F_y=-\tau_{xy}\ dA_x\\ \]

On the bottom face we have

\[ F_y=-\sigma_y\ dA_y\\ F_x=-\tau_{xy}\ dA_y\\ \]

Both faces exhibit negative signs because the stresses act to the left (negative x) and down (negative y).

On the inclined face we have

\[ \begin{aligned} &F_x=\sigma_n\ dA'\ cos(\theta)-\tau_{nt}\ dA' sin(\theta)\\ &F_y=\sigma_n\ dA'\ sin(\theta)+\tau_{nt}\ dA' cos(\theta)\\ \end{aligned} \]

2. Express dAx and dAy in terms of dA’.

Using trigonometry results in

\[ \begin{aligned} dA_x & =dA'\sin(\beta)\\ &=d A^{\prime} \cos (\theta)\\ \end{aligned} \]

\[ \begin{aligned}dA_y & =dA'\cos(\beta)\\&=d A^{\prime} \sin (\theta)\\\end{aligned} \]

3. Substitute these area expressions into the force equations and write the force equilibrium equations.

\[ \begin{gathered}\sum F_x=-\sigma_x\ d A^{\prime} \cos (\theta)-\tau_{xy}\ d A^{\prime} \sin (\theta)+\sigma_n\ dA' cos(\theta) -\tau_{n t}\ d A^{\prime} \sin (\theta)=0 \\[10pt]\sum F_y=-\tau_{xy}\ d A^{\prime} \cos (\theta)-\sigma_y\ d A^{\prime} \sin (\theta) +\sigma_n\ dA' sin(\theta)+\tau_{n t}\ dA'\ cos(\theta)=0\end{gathered} \]

4. Solve the equilibrium equations for σn and τnt and simplify.

\[ \boxed{\begin{aligned} & \sigma_n=\sigma_x \cos ^2(\theta)+\sigma_y \sin ^2(\theta)+2 \tau_{x y} \sin (\theta) \cos (\theta) \\[10pt] & \tau_{n t}=-\left(\sigma_x-\sigma_y\right) \cos (\theta) \sin (\theta)+\tau_{x y}\left(\cos ^2(\theta)-\sin ^2(\theta)\right) \end{aligned}} \tag{12.1}\]

These equations are the stress transformation equations.

Alternatively, implementing the trigonometric identities results in

\[ \begin{gathered} \cos ^2(\theta)=\frac{1+\cos (2 \theta)}{2} \\ \sin ^2(\theta)=\frac{1-\cos (2 \theta)}{2} \\ \sin (2 \theta)=2 \sin (\theta) \cos (\theta) \\ \cos (2 \theta)=\cos ^2(\theta)-\sin ^2(\theta) \end{gathered} \]

The transformation equations can also be expressed as

\[ \boxed{\begin{aligned} \sigma_n & =\frac{\sigma_x+\sigma_y}{2}+\frac{\sigma_x-\sigma_y}{2} \cos (2 \theta)+\tau_{x y} \sin (2 \theta) \\[10pt] \tau_{n t} & =-\frac{\sigma_x-\sigma_y}{2} \sin (2 \theta)+\tau_{x y} \cos (2 \theta) \end{aligned}}\text{ ,} \tag{12.2}\]

𝜎n = Average normal stress perpendicular to the inclined plane [Pa, psi]

𝜏nt = Average shear stress parallel to the inclined plane [Pa, psi]

𝜎x = Average normal stress in the x direction before any transformation [Pa, psi]

𝜎y = Average normal stress in the y direction before any transformation [Pa, psi]

𝜏xy = Average shear stress in the x-y plane before any transformation [Pa, psi]

𝜃 = Angle between x-axis and n-axis [\(^\circ\), rad]

Either Equation 12.1 or Equation 12.2 will work to perform stress transformations. Which set to use is determined by personal preference.

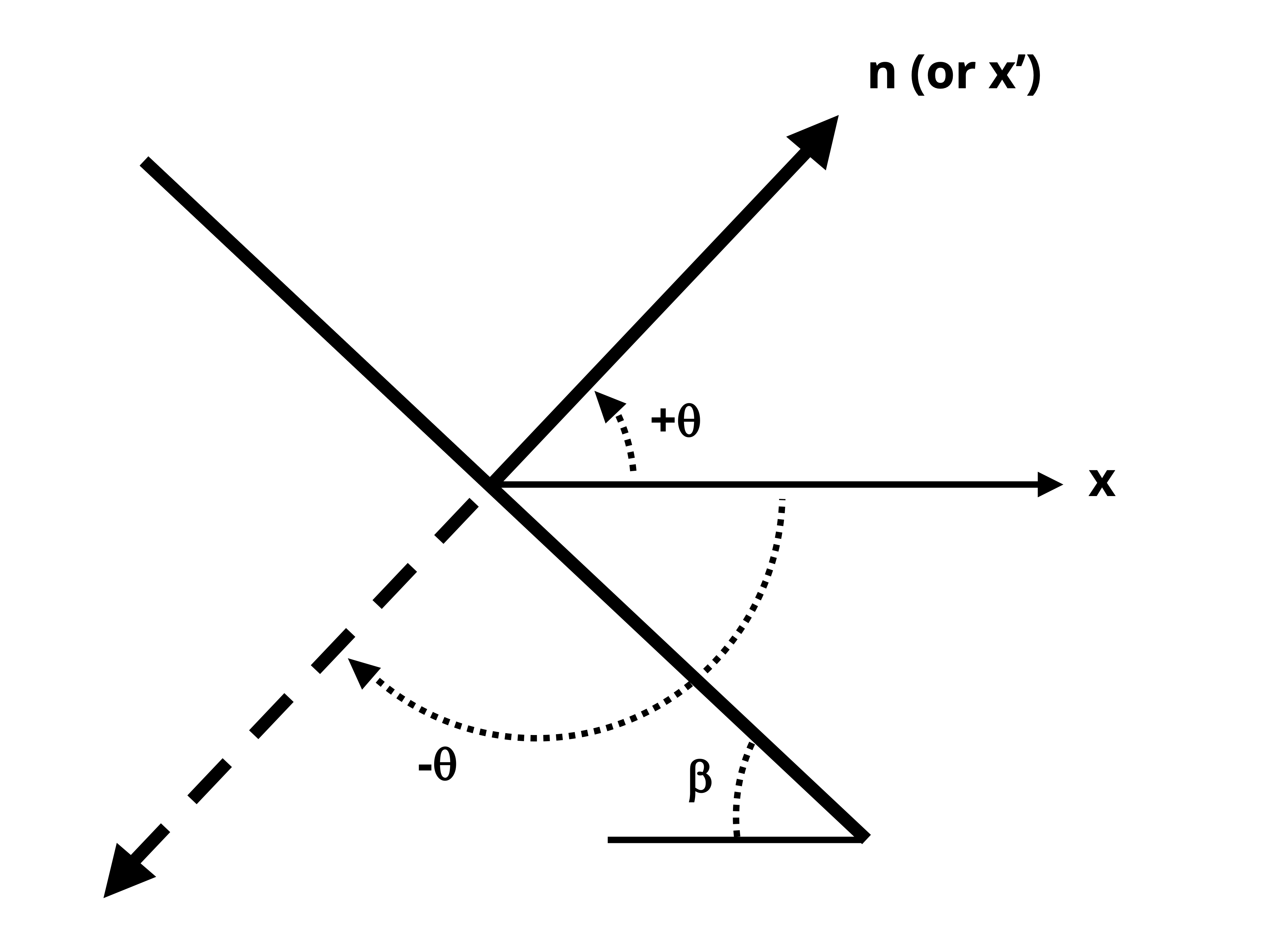

12.2.2 Using the Stress Transformation Equations

Whereas the n and t directions have referred to the directions normal and parallel to an incline, a planar element will have two normal directions, as represented by x,y and x’, y’ in Figure 12.6. In transforming stresses from the x-y plane to the x’-y’ plane, we can distinguish between the two normal stresses by the angle used in the stress transformation equation for 𝜎n. Given how 𝛳 was defined in the derivation of the transformation equations, the following is true:

\[ \sigma_{x'}=\sigma_n(\theta)\\ \sigma_{y'}=\sigma_n(\theta+90^\circ)\\ \tau_{x' y'}=\tau_{nt}(\theta) \]

Another way to quickly determine σy’ once σx’ is known is to apply the concept of stress invariance, where the sum of the normal stresses remains constant across different planes.

\[ (\sigma_x\ +\sigma_y)=constant \]

or

\[ \boxed{(\sigma_{x'}\ +\sigma_{y'})=(\sigma_x\ +\sigma_y)} \tag{12.3}\]

It is imperative to understand which angle to substitute into the given transformation equations, including whether the angle is positive or negative. To ensure the correct angle and sign are used, refer to Figure 12.7 and take the following steps:

Draw a line that represents one side of the plane of interest.

Draw the x-axis (positive to the right).

Draw the axis normal to the plane of interest. Whether you draw the normal axis oriented counterclockwise or clockwise from the x-axis doesn’t matter as long as you use the correct magnitude and sign for the corresponding θ (see step 4).

Determine the angle that leads from the x-axis to the normal axis. This angle is θ. If the direction from the x-axis to the normal axis is counterclockwise, then θ is positive. If the direction from the x-axis to the normal axis is clockwise, then θ is negative.

12.2.3 Equation Inputs for Planes Other than x-y

In some cases the reference stress state may not be in the x-y plane, or the x-axis and y-axis may be oriented differently from the orientation in Figure 12.5. In these cases adjustments are required to implement the transformation equations to ensure consistency of inputs with how the equations were derived.

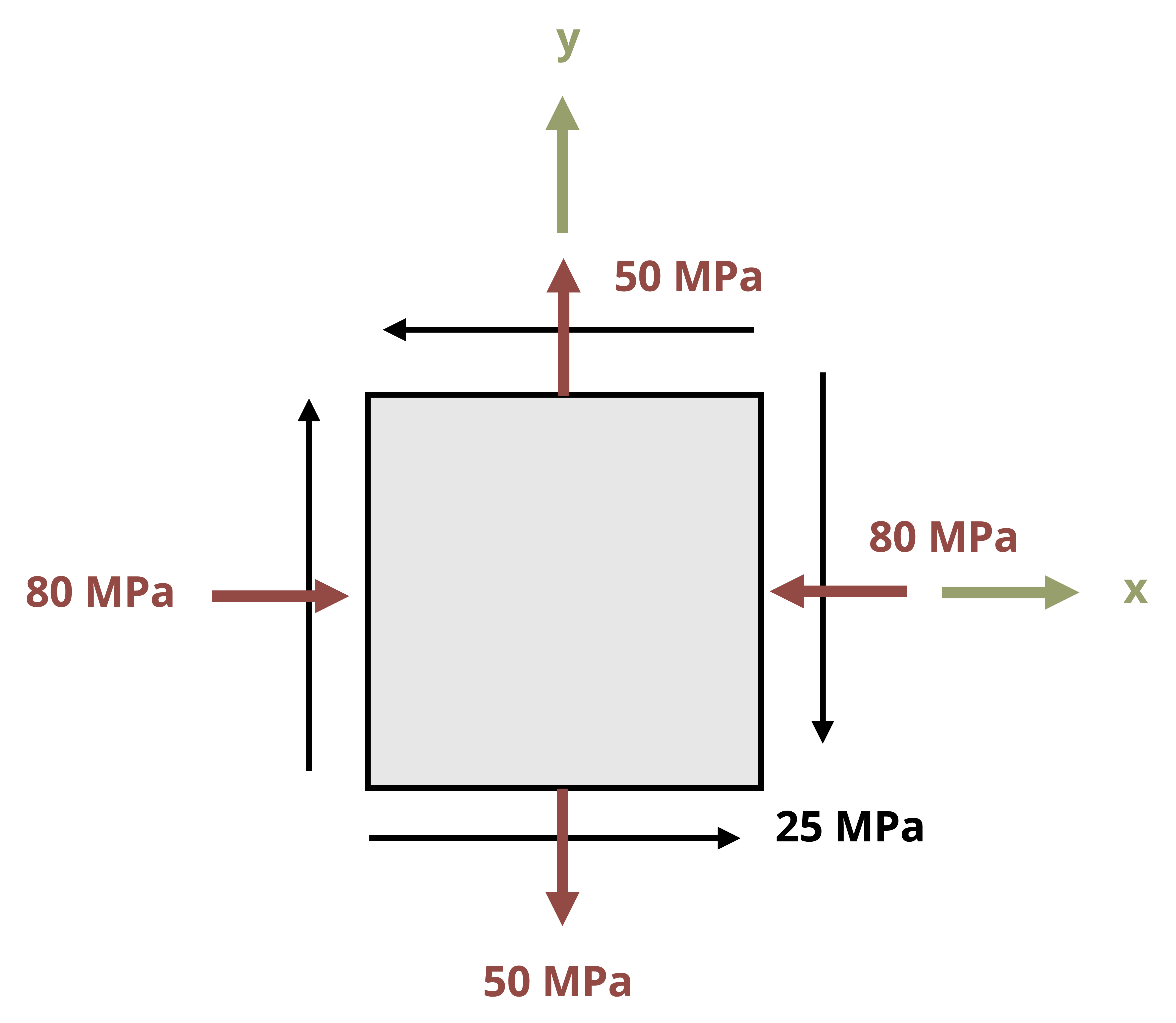

As an example, consider the reference stress state in Figure 12.8. As given, you might question which stress to substitute for 𝜎x and which to substitute for 𝜎y. Keeping in mind that the transformation equations were derived from a coordinate system in which the horizontal axis is positive to the right and the vertical axis is positive upward, we can ensure consistency with the inputs by reorienting the reference stress element in the same way, as is also shown in Figure 12.8. We can then attribute the coordinate designated to the horizontal direction to correspond to the x terms in the transformation equations, and likewise the coordinate designated to the vertical direction to correspond to the y terms in the transformation equations. In the case of the stress state in Figure 12.8, we would substitute -150 MPa for 𝜎x, 90 MPa for 𝜎y, and 16 MPa for τxy.

Example 12.1 and Example 12.2 illustrate the use of the stress transformation equations.

12.3 Principal Stresses and Max/Min Shear Stress

Click to expand

Often the plane we are the most concerned with is the one where the normal stress or the shear stress is at a maximum because it is where failure is most likely to occur. The maximum and minimum normal stresses are referred to as the principal stresses (σ1 and σ2), and the planes on which they act are the principal planes. The principal planes are described by angles of rotation,θp1 and θp2, from the reference plane for which the general stress state as obtained. The maximum and minimum shear stresses are simply referred to as the maximum and minimum shear stress respectively, and the planes on which they occur are referred to simply as the planes of maximum and minimum shear stress (denoted as angles θs1 and θs2).

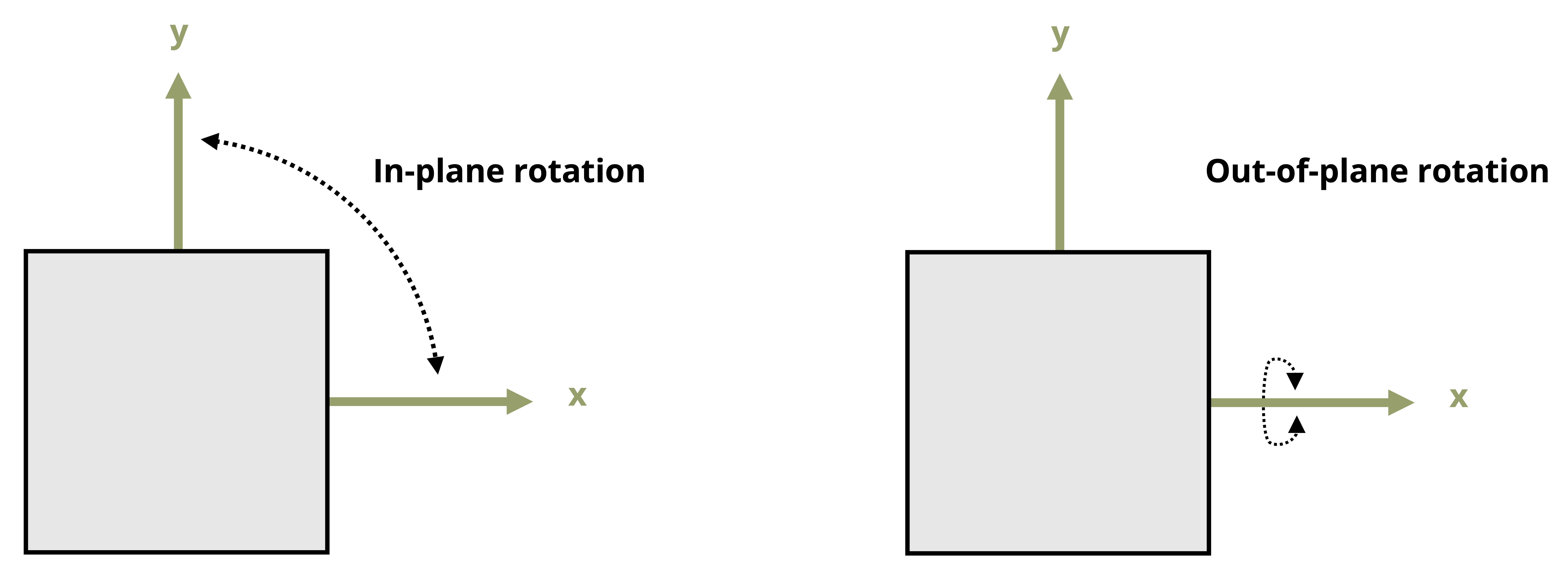

Important to note here is that only rotations within a two-dimensional plane are considered in this section. As discussed in Section 12.5, the principal planes and principal stresses are the same even when we consider out-of-plane rotation of the stress element (see Figure 12.9), but the maximum shear stress could be different. Therefore the maximum and minimum shear stress as determined by the derived equations below will be referred to as the max/min in-plane shear stress.

As we rotate the stress element, the normal stress changes in a manner predictable with the stress transformation equations. Figure 12.10 shows the variation of normal stress σx’ with angle θ. A similar graph could be drawn for τx’y’. Based on the equations and the plots, we know that the max and min stresses will occur at angles 90° apart from one another.

From calculus we know that the maximums and minimums of a function that result from varying a single variable can be found by setting the derivative of the function with respect to that variable equal to 0 and then solving the resulting equation for the variable in question. Plugging the variable back into the original equation gives the corresponding maximum or minimum value of the function. This is also equivalent to finding where the slope of the function is equal to 0. Thus, to find the angles for which the normal stress and in-plane shear stresses are at extremes, we can simply set the derivatives of the transformation equations (Equation 12.1 or Equation 12.2) with respect to θ equal to 0, and solve for the θ values.

Using Equation 12.2 (though Equation 12.1 would yield the same results)

\[ \begin{aligned} & \frac{d \sigma_n}{d \theta}=-\left(\sigma_x-\sigma_y\right) \sin \left(2 \theta_p\right)+2 \tau_{x y} \cos \left(2 \theta_p\right)=0 \\[10pt] & \frac{d \tau_{n t}}{d \theta}=-\left(\sigma_x-\sigma_y\right) \cos \left(2 \theta_s\right)-2 \tau_{x y} \sin \left(2 \theta_s\right)=0 \end{aligned} \]

Note that θ is subscripted with a p in the first equation because this angle represents a principal plane as defined. Similarly, θ is subscripted with an S in the second equation because this angle represents a plane of maximum (max) or minimum (min) in-plane shear stress.

These equations can be rearranged to isolate tan(2θ) on one side and subsequently used to find θp and θs values.

\[ \boxed{\begin{aligned} \tan \left(2 \theta_p\right) & =\frac{2 \tau_{x y}}{\left(\sigma_x-\sigma_y\right)} \\[10pt] \tan \left(2 \theta_s\right) & =-\frac{\left(\sigma_x-\sigma_y\right)}{2 \tau_{x y}} \end{aligned}}\text{ ,} \tag{12.4}\]

𝜃p = Orientation a principal plane with respect to the x-axis [\(^\circ\), rad]

𝜃s = Orientation of the maximum or minimum in-plane shear plane with respect to the x-axis [\(^\circ\), rad]

𝜏xy = Average shear stress in the x-y plane before any transformation [Pa, psi]

𝜎x = Average normal stress in the x direction before any transformation [Pa, psi]

𝜎y = Average normal stress in the y direction before any transformation [Pa, psi]

Once the angles associated with the planes of extreme stresses are determined, they can be substituted into Equation 12.1 or Equation 12.2 along with the stresses in the given plane to find the principal stresses and max/min in-plane shear stress.

Here are a few calculation details that are helpful to remember:

The inverse tangent function has two possible solutions. One solution is the angle that will be reported by a calculator, and the other possible answer is that angle plus or minus 180°. So if we take the inverse tangent of the expressions of Equation 12.4 and then divide that result by 2, we get one of the solution angles. Then adding or subtracting 90° to that angle gives the second. This applies for the θp and the θs values.

By convention the most positive of the two principal stresses is denoted as σ1. The other principal stress is then σ2. The angle that produces that σ1 stress is θp1, and the angle that produces σ2 is θp2.

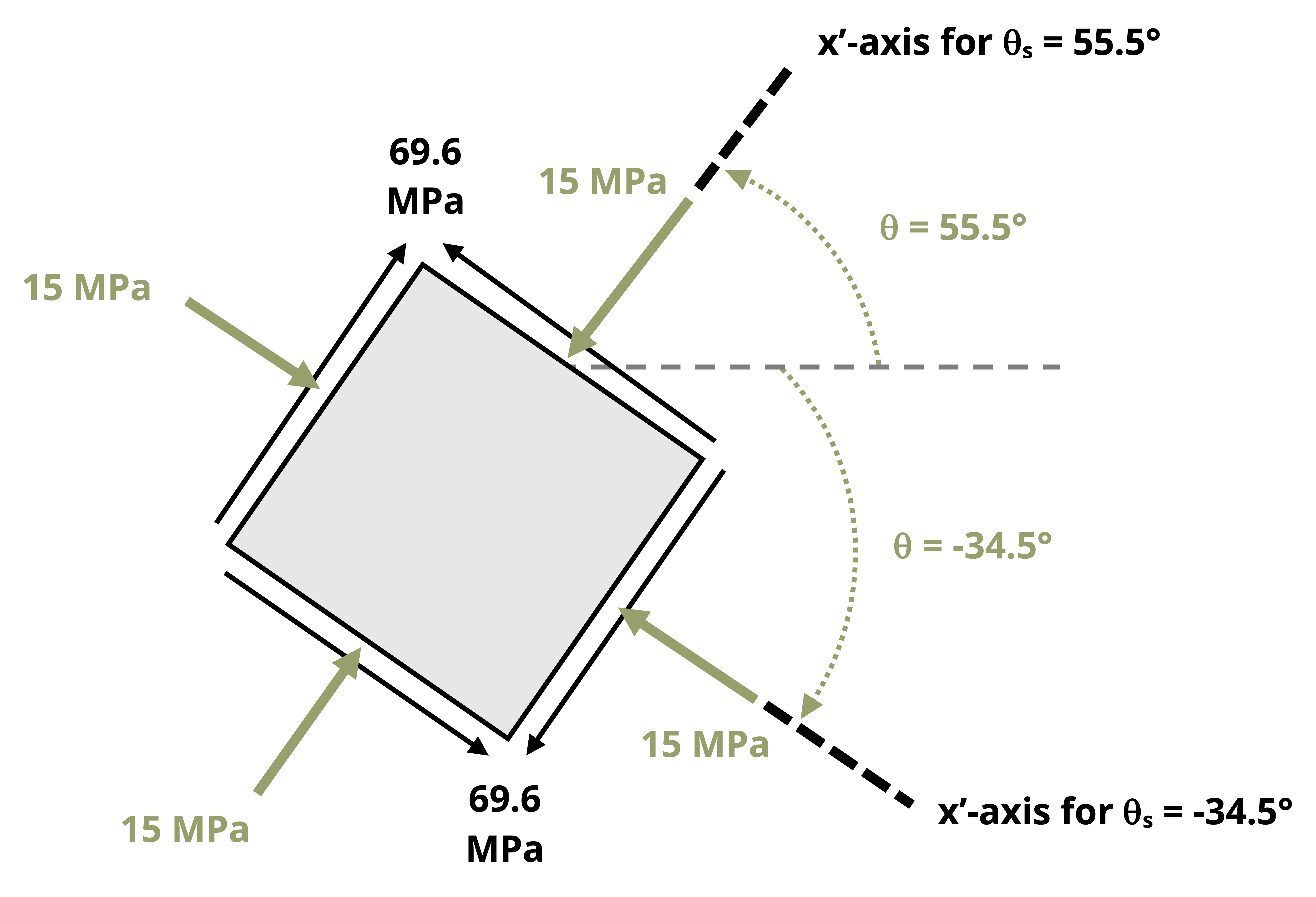

The max/min in-plane shear stress will always turn out to be equal in magnitude but opposite in sign—in other words, the minimum shear stress is always the negative of the maximum shear stress. As with the principal planes and stresses, substitute one of the θs angles into the shear stress transformation equation to determine which angle corresponds to the maximum in-plane shear stress and which corresponds to the minimum.

The angles of max/min shear stress are 90° apart from each other and 45° apart from the principal directions. For example, if one principal stress is found to be 40°, then the other principal direction can be determined as either 40° + 90° =130° or 40° - 90° = -50°. The angles of max/min in-plane shear stress can then be determined as either 40° + 45° = 95° or 40° -45° = - 5°. It is also acceptable to add or subtract 45° from 130° or from –50°.

Given the variety of possible correct angles, here we use the convention that principal directions and angles of max/min shear stress are reported as the ones in the range –90° ≤ θ ≤ +90°.

If desired, the principal stresses and max/min shear stress can also be calculated directly without first finding the principal directions. The following equations arise from some equation manipulation which will not be detailed here, but can be used generally. Adding the term under the square root will give either the max or min stress and subtracting will give the other.

\[ \boxed{\begin{gathered} \sigma_{1,2}=\frac{\sigma_x+\sigma_y}{2} \pm \sqrt{\left(\frac{\sigma_x-\sigma_y}{2}\right)^2+\tau_{x y}{ }^2} \\[10pt] \tau_{x \prime y^{\prime}}= \pm \sqrt{\left(\frac{\sigma_x-\sigma_y}{2}\right)^2+\tau_{x y}{ }^2} \end{gathered}}\text{ ,} \tag{12.5}\]

𝜎1,2 = Principal stresses [Pa, psi]

𝜎x = Average normal stress in the x direction before any transformation [Pa, psi]

𝜎y = Average normal stress in the y direction before any transformation [Pa, psi]

𝜏xy = Average shear stress in the x-y plane before any transformation [Pa, psi]

Some useful conclusions that can be drawn simply by studying the principal plane and plane of max/min shear stress equations are as follows:

Setting the shear stress transformation equation given in Equation 12.1 or Equation 12.2 equal to 0 results in the same equation for tan(2θ) as the tan(2θp) equation in Equation 12.4. We can then conclude that shear stress is 0 on the principal planes. It can also be said that if the shear stress is found to be 0 on any given plane, then that plane must be a principal plane.

The equation for tan(2θs) is the negative inverse of the equation for tan(2θp). This means that 2θs = 2θp ± 90° or θs = θp ± 45°. Recognizing this can enable us to calculate one set of angles more efficiently once the other is found.

When either of the θs angles is substituted into the normal stress transformation equation, the normal stress will always work out to be the average stress \(\left(\frac{\sigma_x+\sigma_y}{2}\right)\). Once again this recognition can help make determining the total stress state on the plane of in-plane max/min shear stress more efficient.

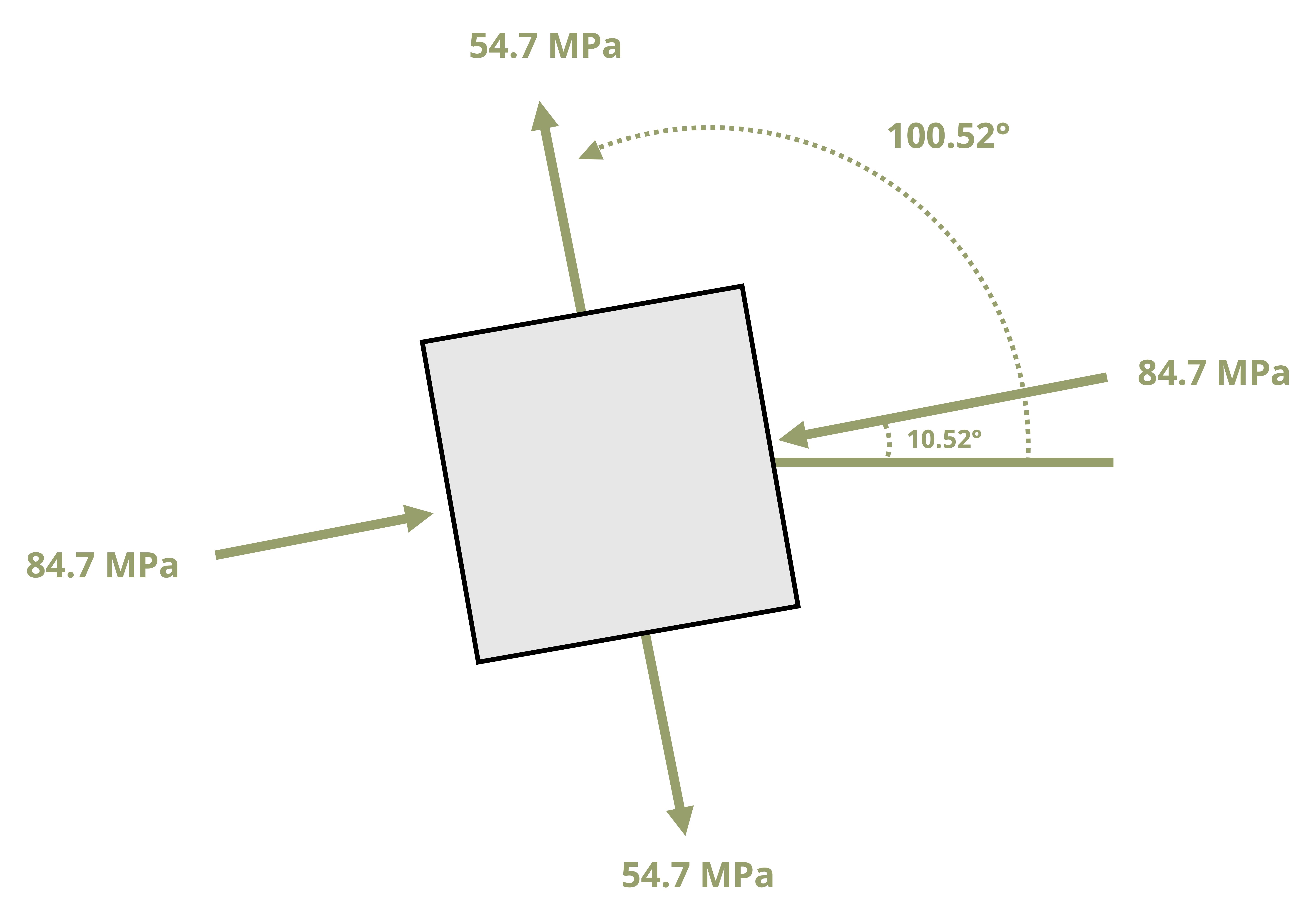

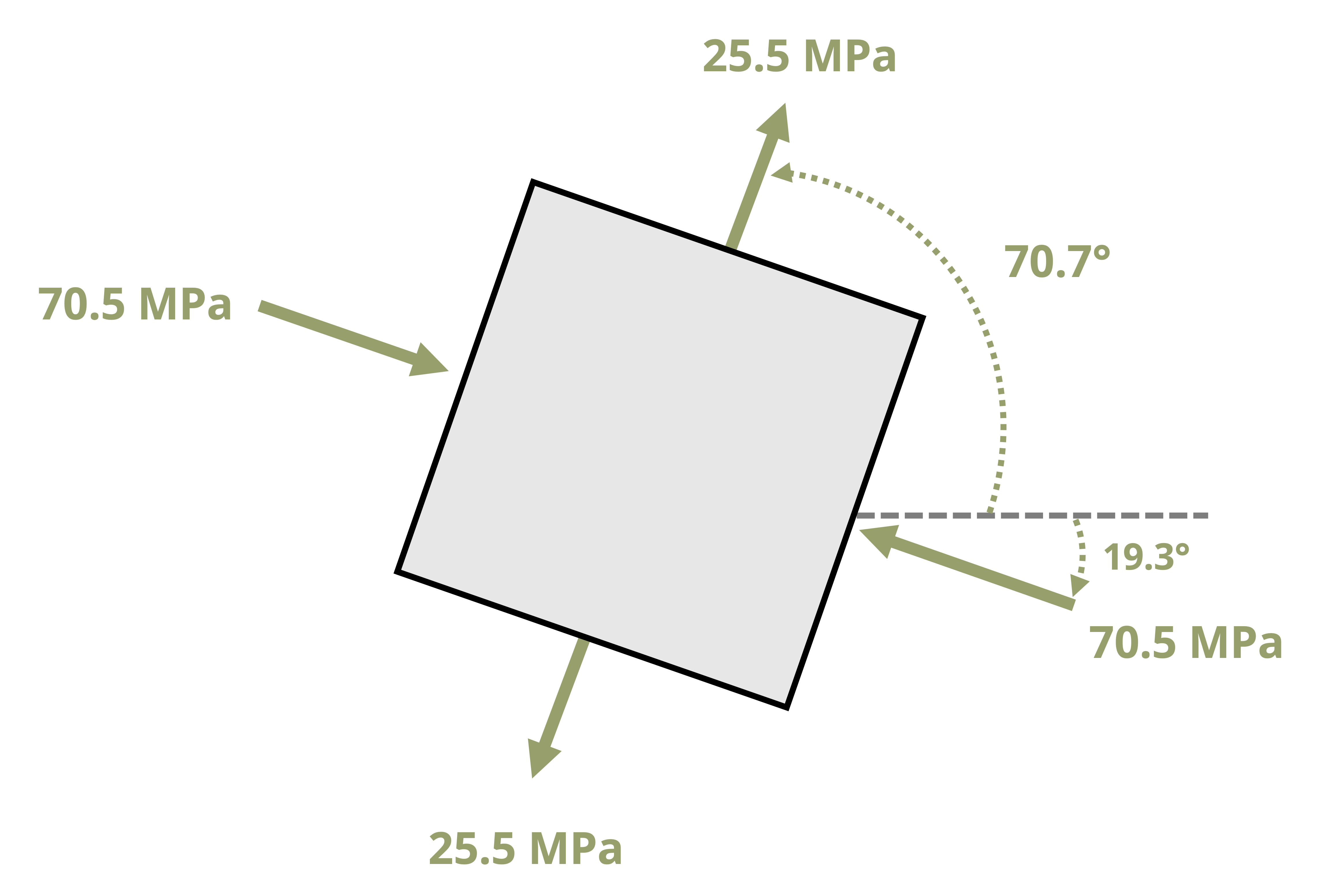

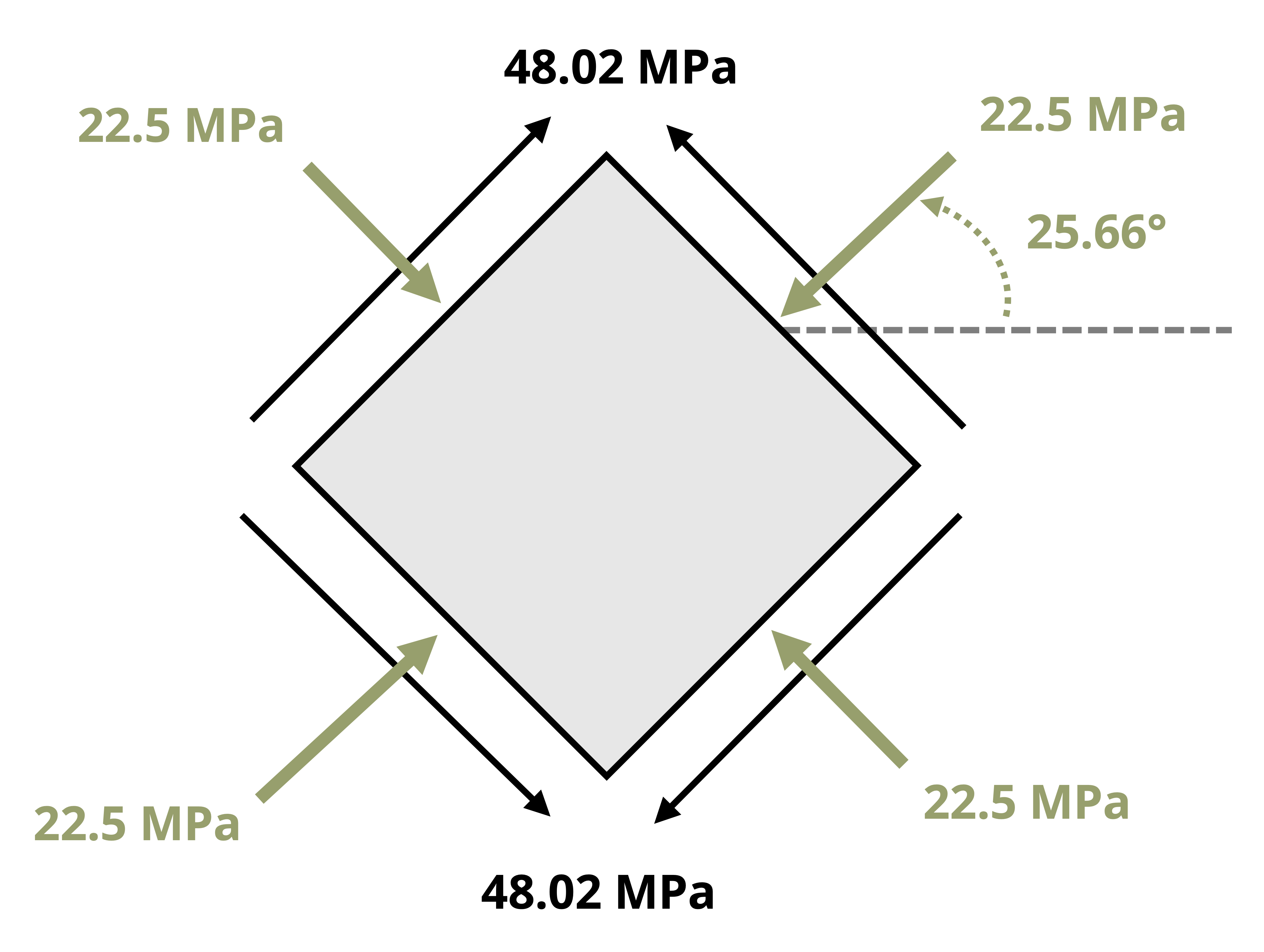

Example 12.3 demonstrates the calculation of the principal stresses, the maximum in-plane shear stress, and the planes where these stresses occur.

12.4 Mohr’s Circle

Click to expand

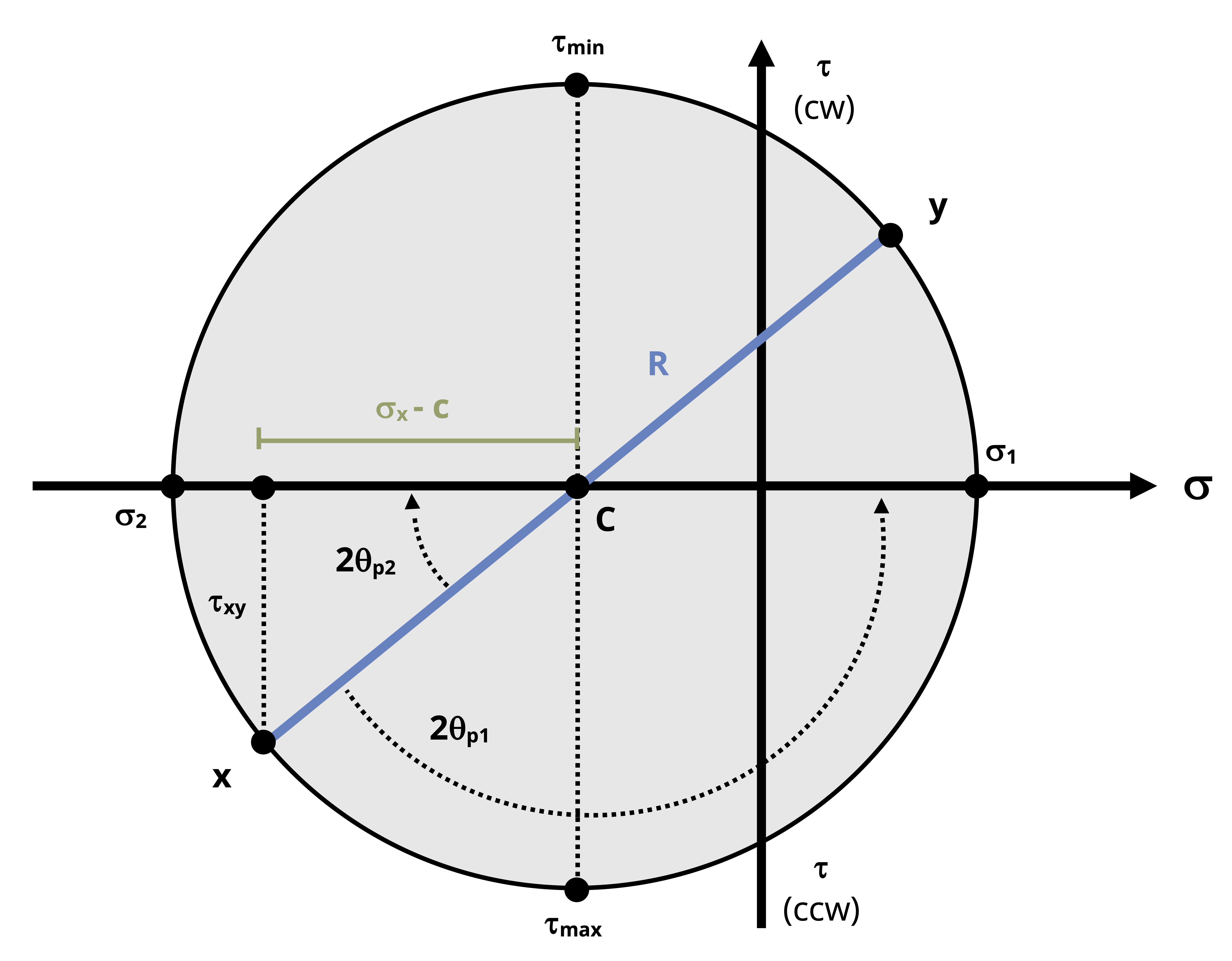

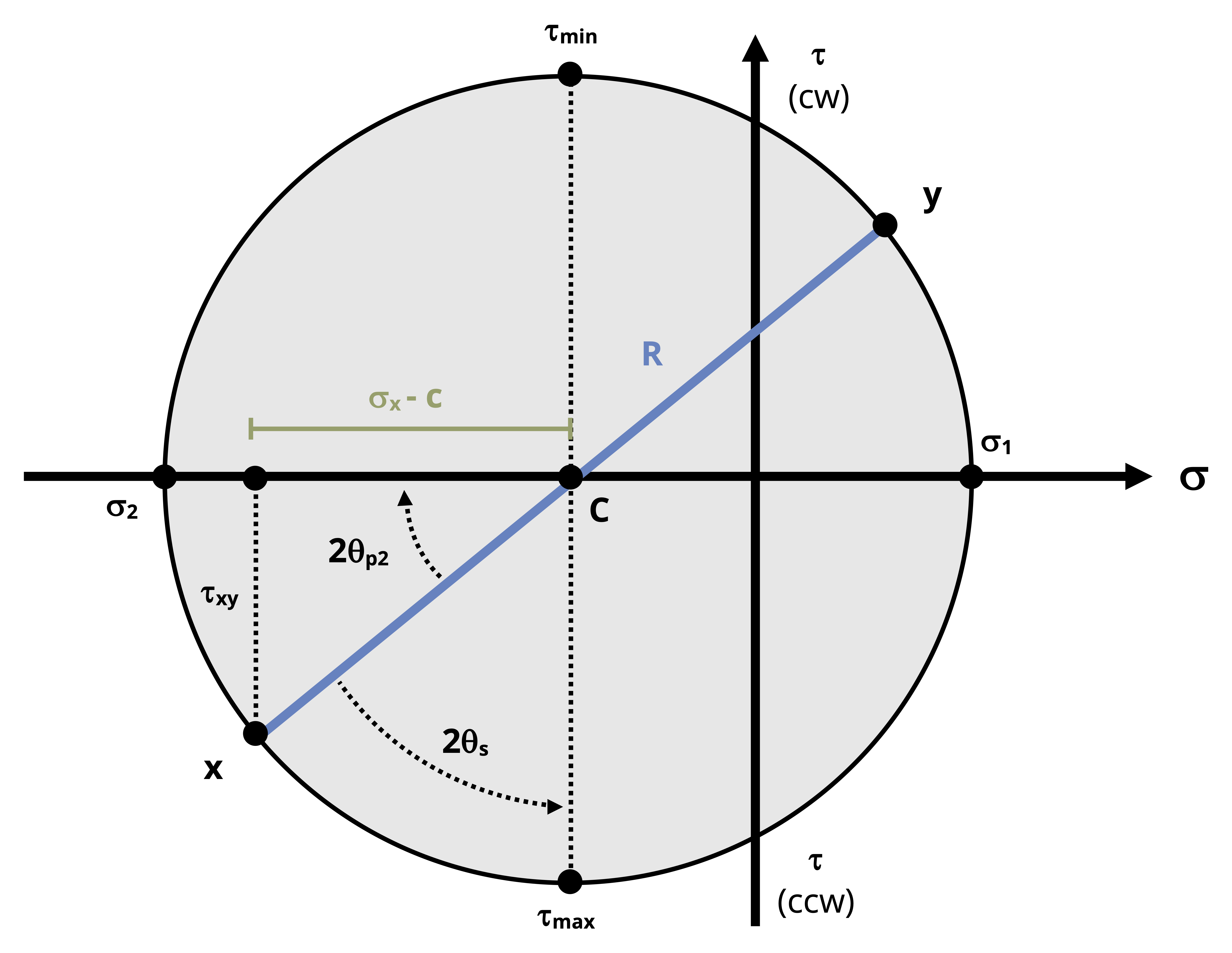

As an alternative to using equations to determine principal planes and stresses as well as max/min shear planes and stresses, use a graphical method known as Mohr’s circle. This method acknowledges that the stress transformation equations are actually parametric equations of a circle. The perimeter of the circle consists of coordinate points that correspond to normal stress on the horizontal axis and shear stress on the vertical axis. The advantage of using Mohr’s circle is that it doesn’t require recalling equations and with some practice can be quick and efficient to use. It is also used more extensively in more advanced topics on material behavior.

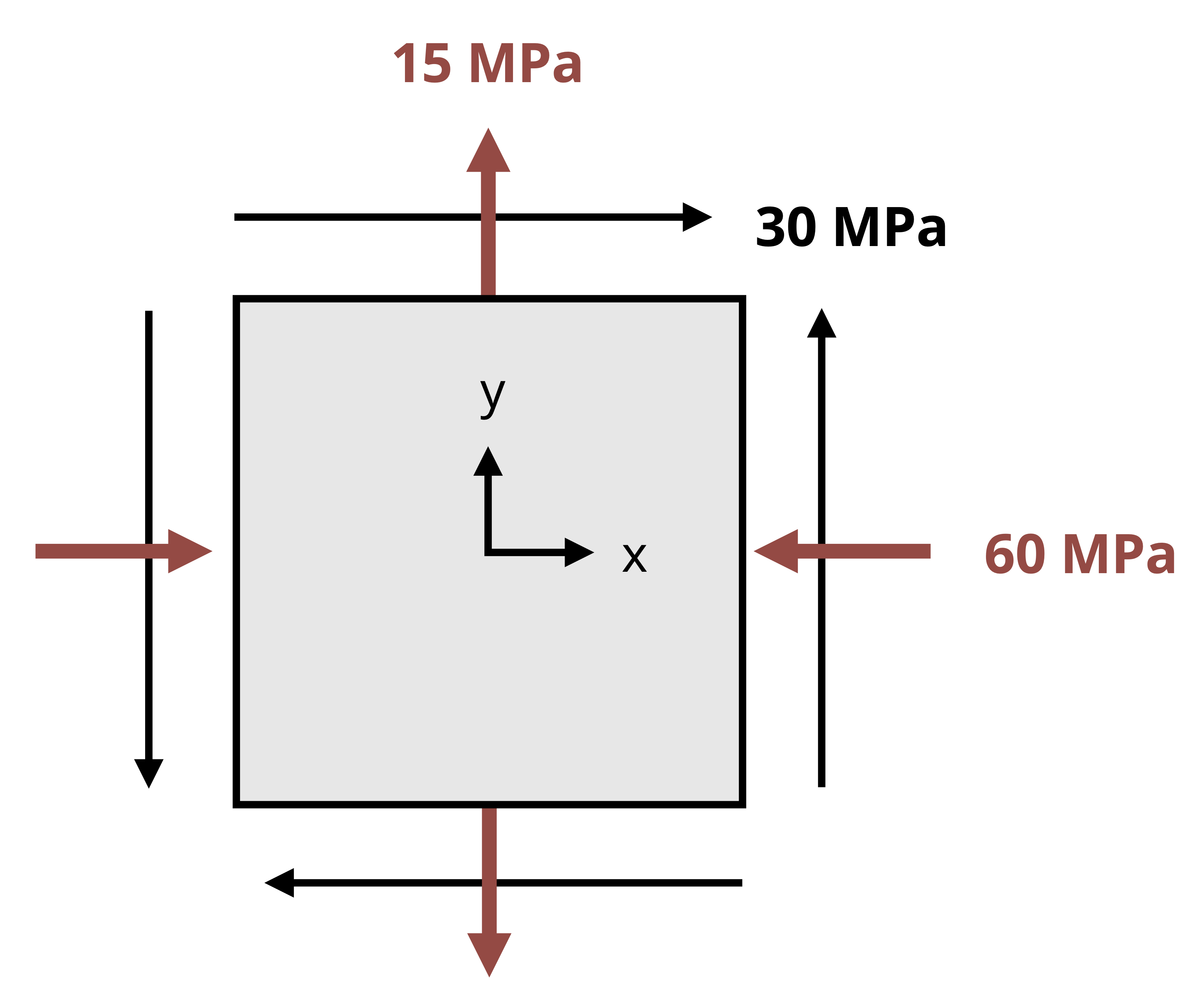

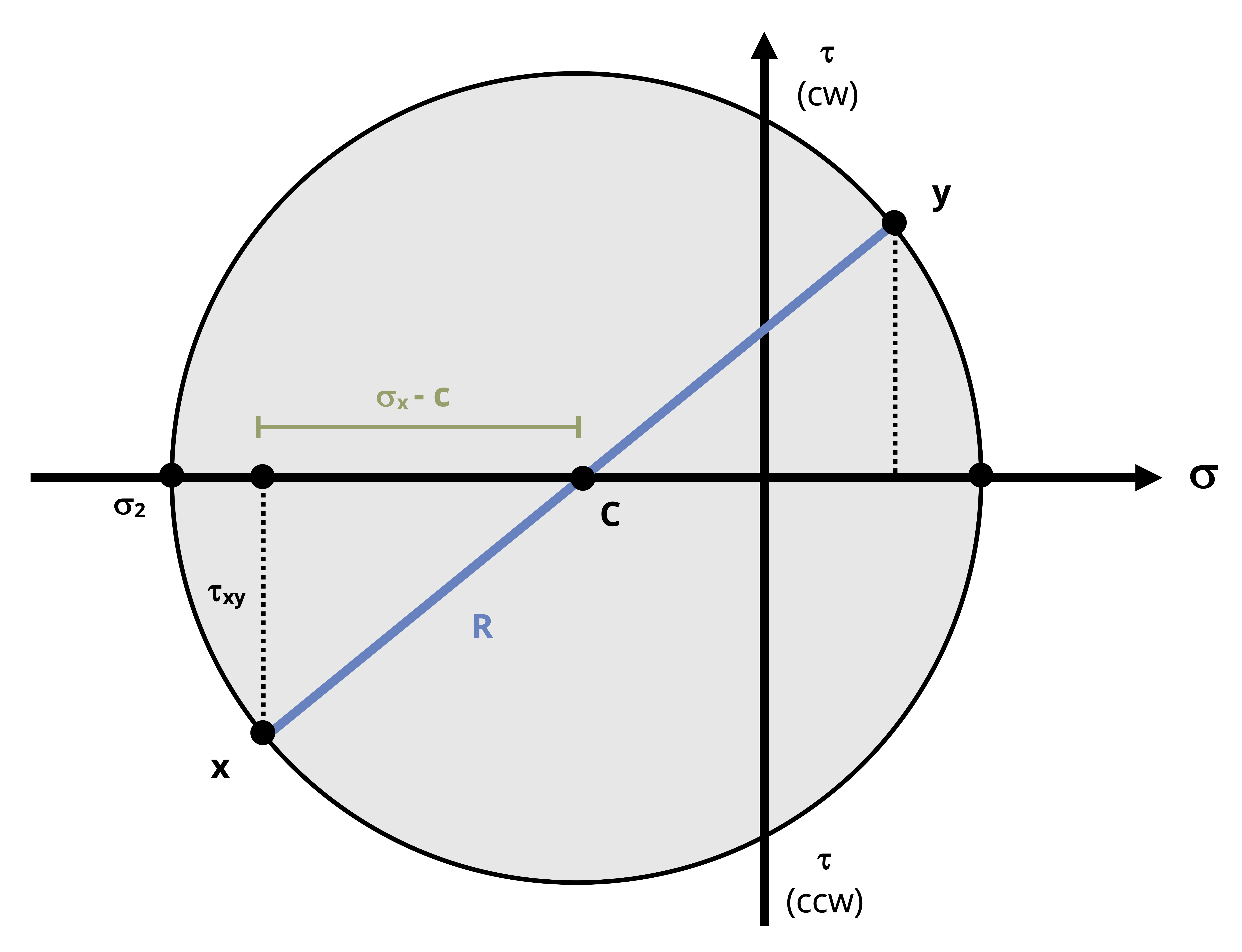

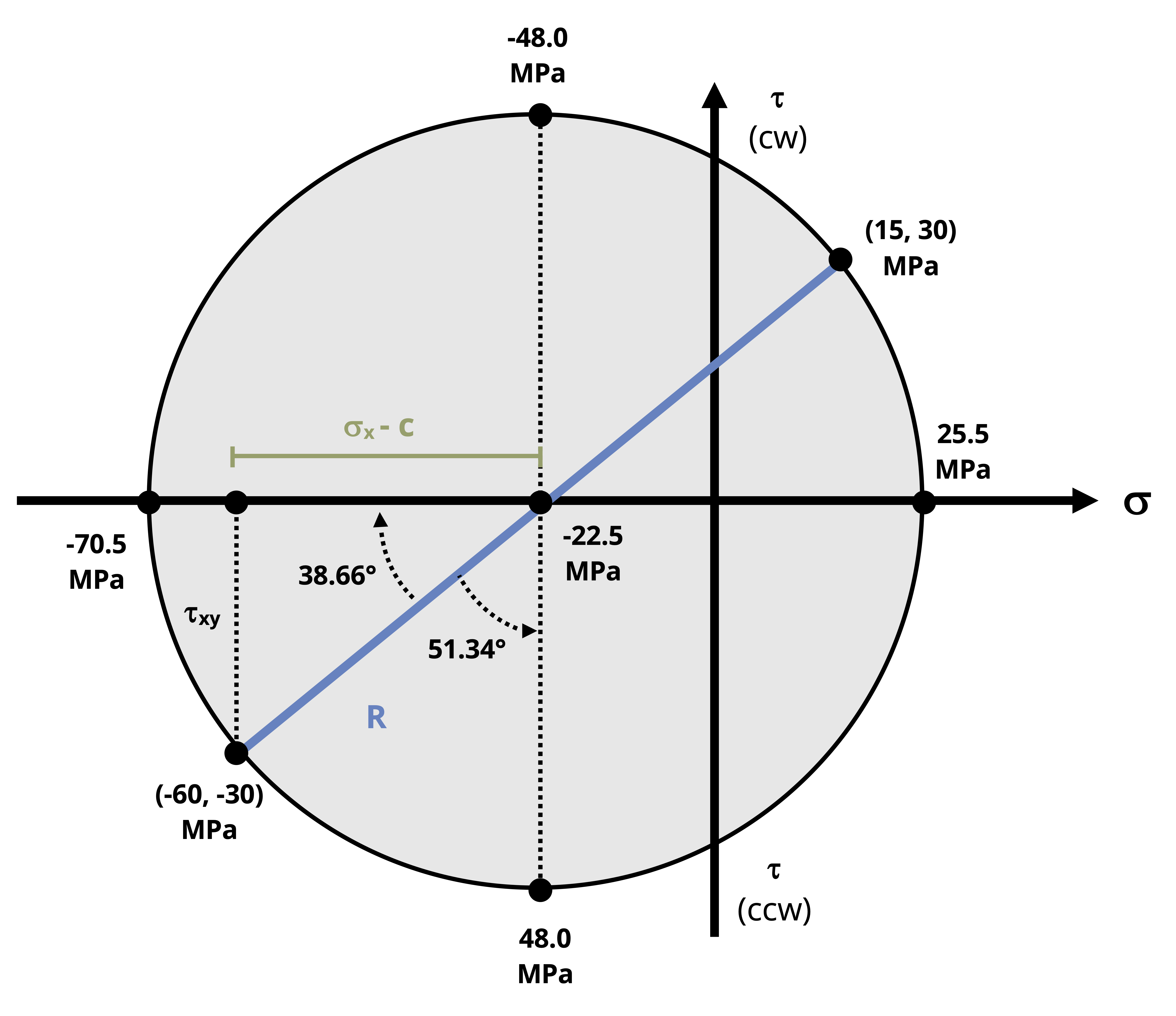

To illustrate the construction of Mohr’s circle, we’ll use the reference stress state element in Figure 12.11.

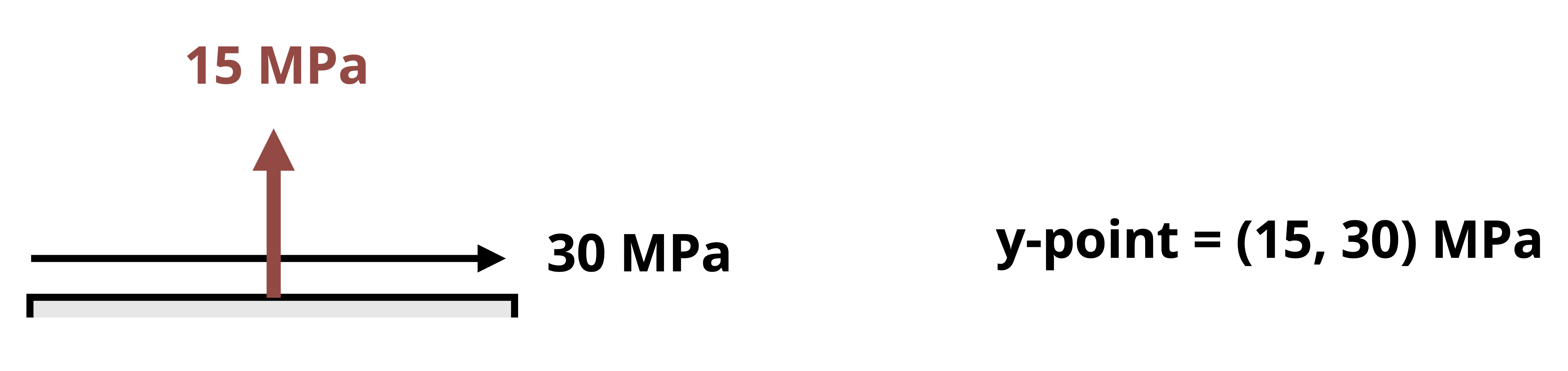

Now we can take the following steps (reference the fully constructed circle in Figure 12.16 for each step):

To start, draw a set of coordinate axes where normal stress will be on the horizontal axis and shear stress will be on the vertical axis. In the figures containing the circle below, the shear stress axis is labeled with a (CW) for clockwise on the positive side and a (CCW) for counterclockwise on the negative side. The reason is explained in step 2.

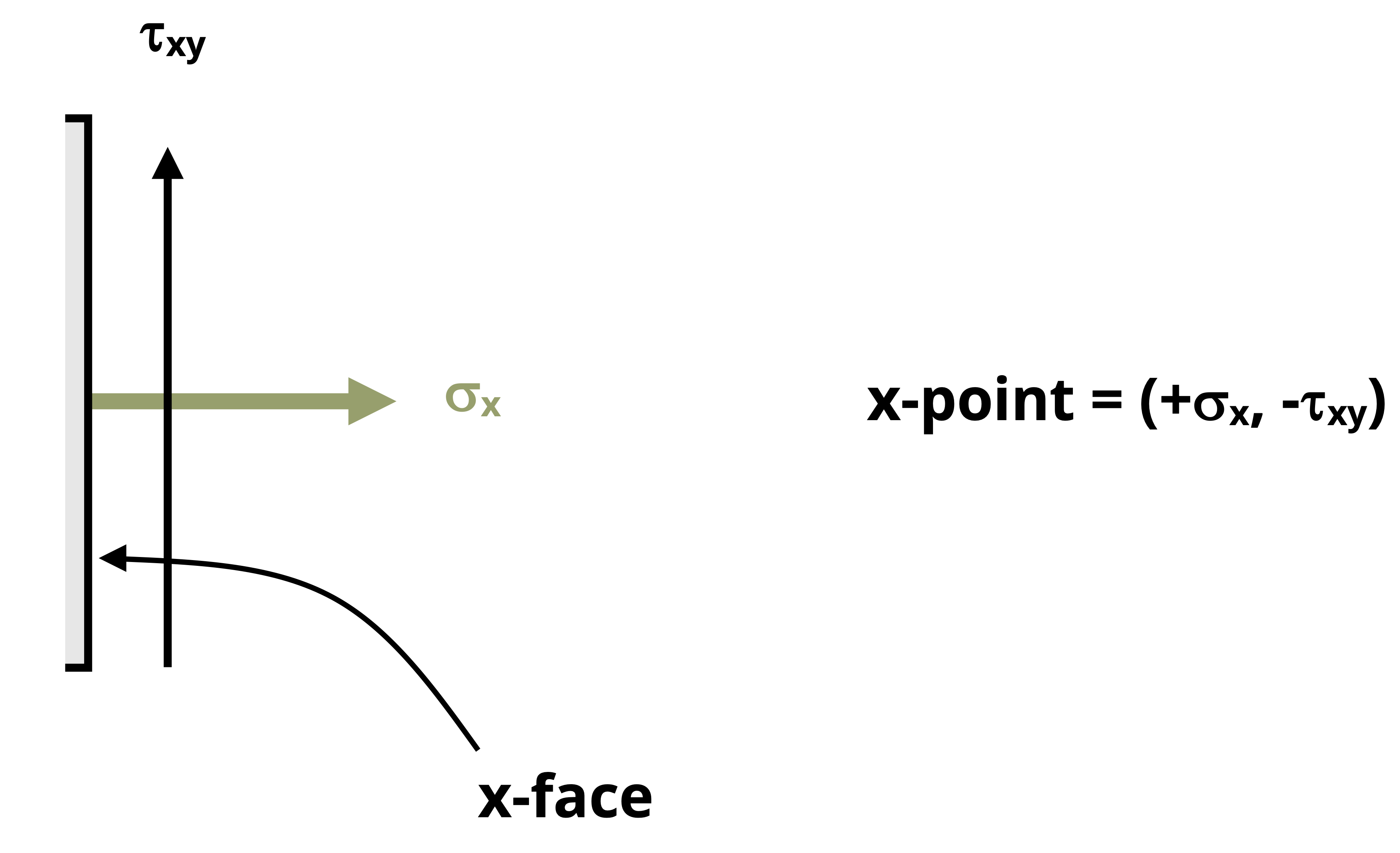

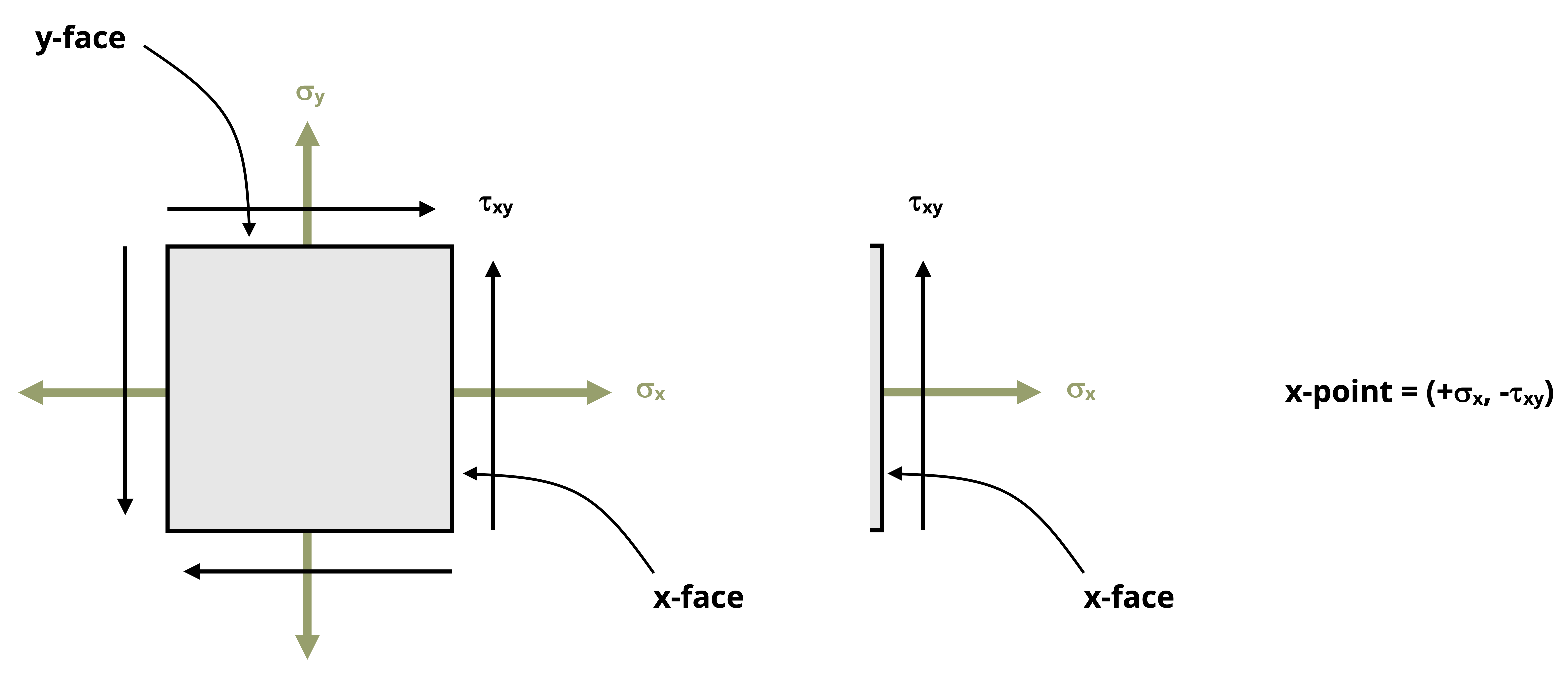

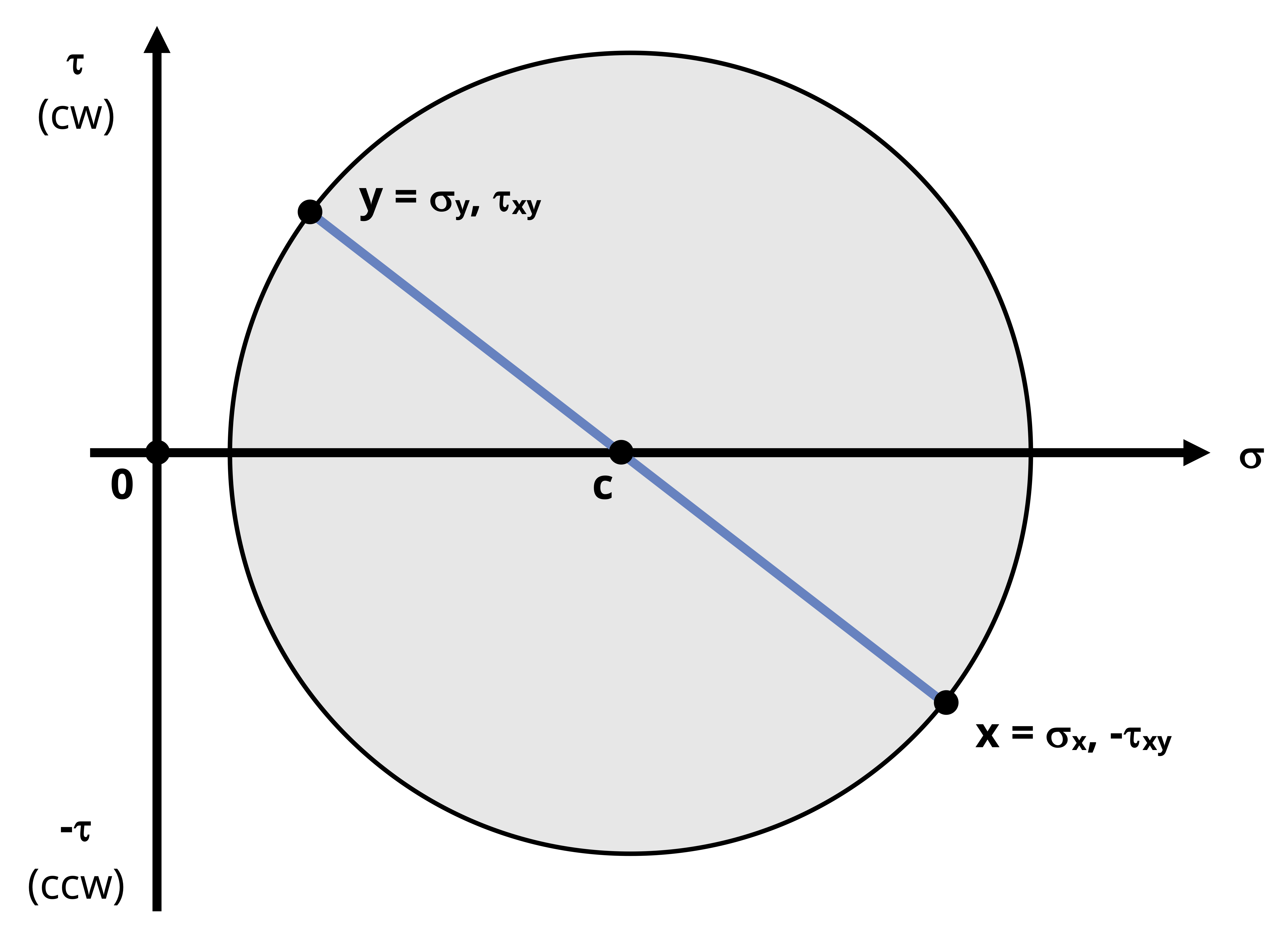

Plot the x point.

The x point represents the stresses applied to the x-face of the stress element, as shown in Figure 12.12, with coordinates (𝜎x, 𝜏xy).

The normal stress coordinate is positive if tensile and negative if compressive.

The sign of the shear stress coordinate depends on the direction of rotation caused by the shear stress on the x-face. If the shear stress causes the element to rotate clockwise, it is a positive coordinate, and if counterclockwise, it is negative.

In Figure 12.11 the normal stress on the x-face is tensile and the upward shear stress tends to cause the stress element to rotate counterclockwise, so the x point is (+σx, -τxy). This point is shown plotted in Figure 12.14.

Figure 12.12: Stresses applied to the positive x-face from the x point

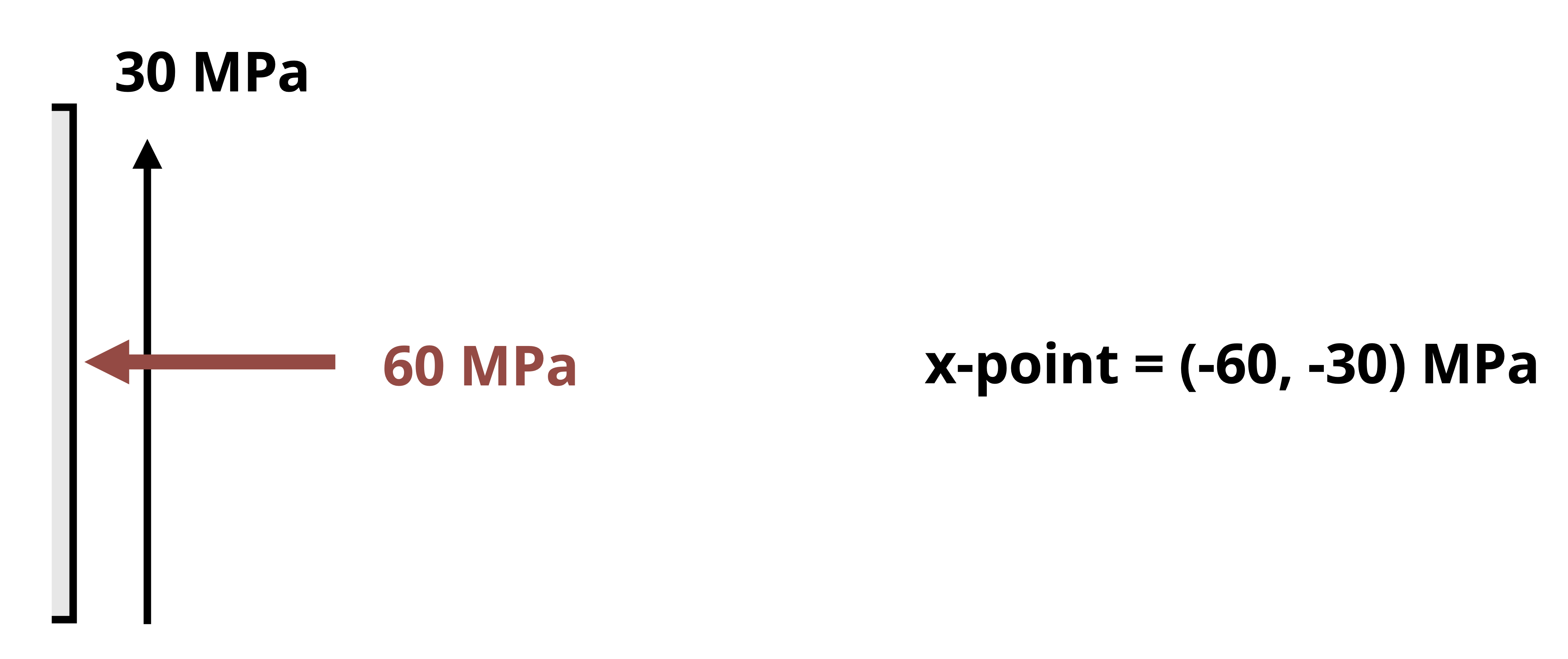

Plot the y point.

Like the x point, the y point consists of coordinates (𝜎y, 𝜏xy). The sign convention is the same as that described for the x point. As illustrated in Figure 12.13 for the stress element given in Figure 12.11, the normal stress on the y-face is tensile and the rightward shear stress tends to cause the element to rotate clockwise, so the y point is (+σy, +τxy). This point is shown plotted in Figure 12.14.

Draw the circle around the diameter formed by connecting the x and y points. The center of the circle is the average normal stress and is denoted with the letter C.

\[ C=(\frac{\sigma_x+\sigma_y}{2},0) \]

Note that the radial line that leads from C to the x point represents the reference x-axis and the radius from C to the y point represents the reference y-axis.

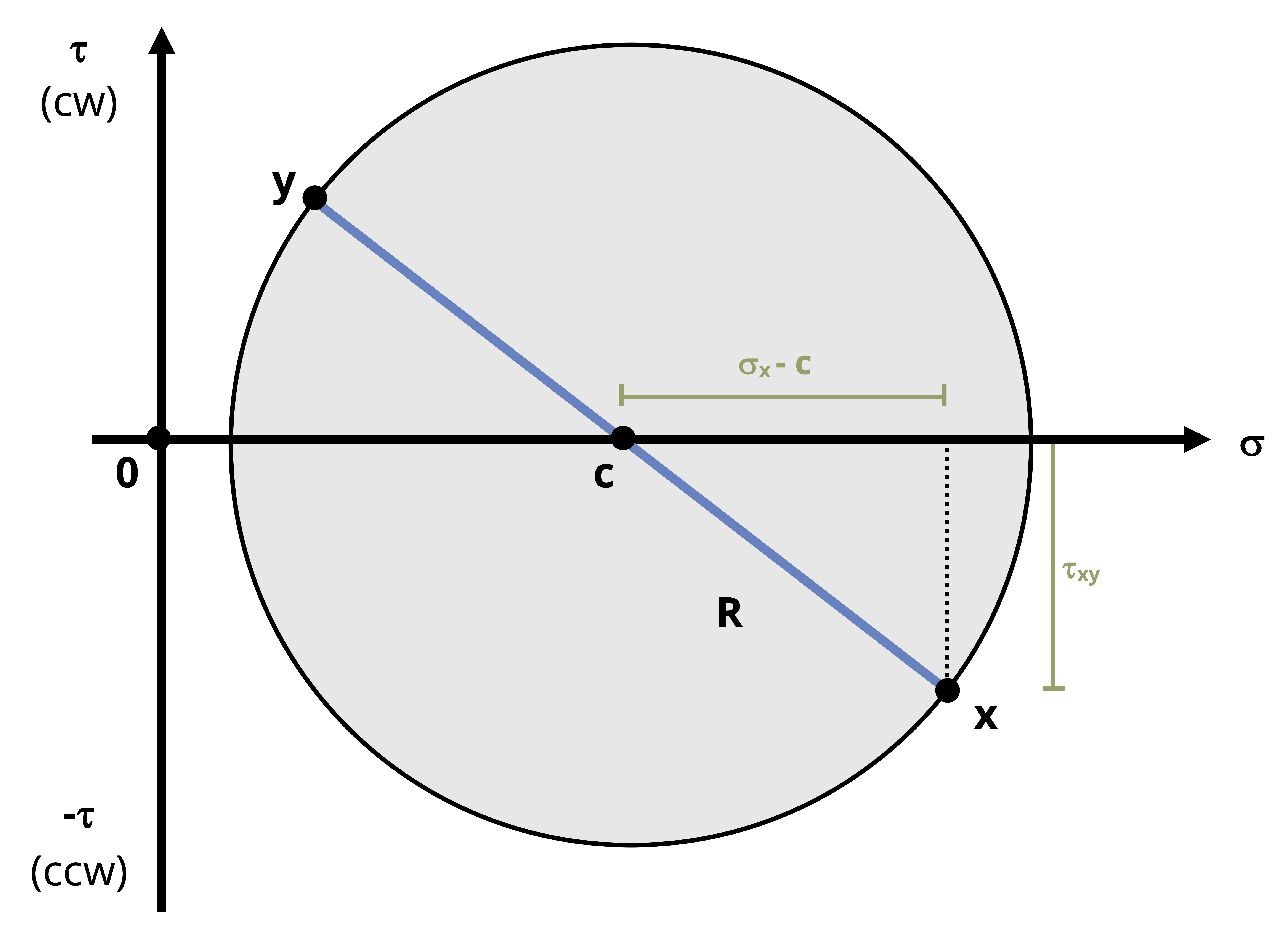

Figure 12.14: Mohr’s circle with the x point, y point, and center point plotted The radius of the circle, R, can be determined using the Pythagorean theorem on the triangle formed between C, σx, and the x point.

\[ R=\sqrt{\left(\sigma_x-C\right)^2+\tau_{x y}^2} \]

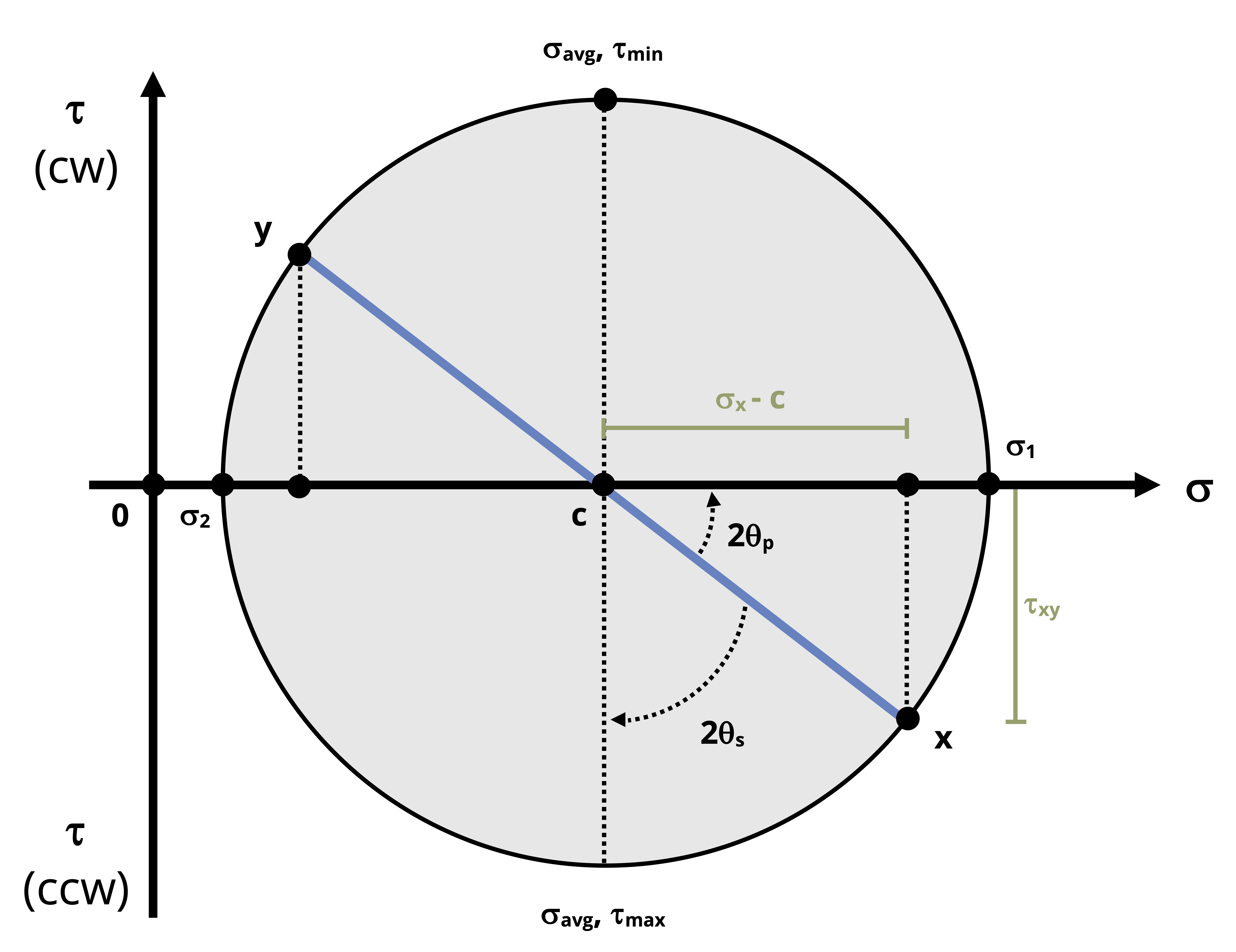

Figure 12.15: The radius of the circle can be found using the Pythagorean theorem Recalling that the shear stress is zero on the principal plane, note that the principal plane is simply the normal stress axis. Thus we can identify σ1 to be the point on the right extreme of the circle and σ2 to be the point on the left extreme of the circle.

\[ \sigma_1=C+R\\ \sigma_2=C-R\\ \]

These points can be found on Figure 12.16.

The max/min in-plane shear stress is at the bottom and top of the circle respectively.

\[ \tau_{max}=+R\\ \tau_{min}=-R \]

The maximum shear stress is at the bottom in accordance with the shear stress plotting convention discussed in steps 2 and 3.

The vertical diameter that connects 𝜏max and 𝜏min is the plane of max/min in-plane shear stress.

Since that plane passes through the center of the circle, we can confirm that the normal stress on the plane of max/min shear stress is \(\mathrm{C}=\sigma_{avg}=\frac{\sigma_x+\sigma_y}{2}\).

These points can be found on Figure 12.16.

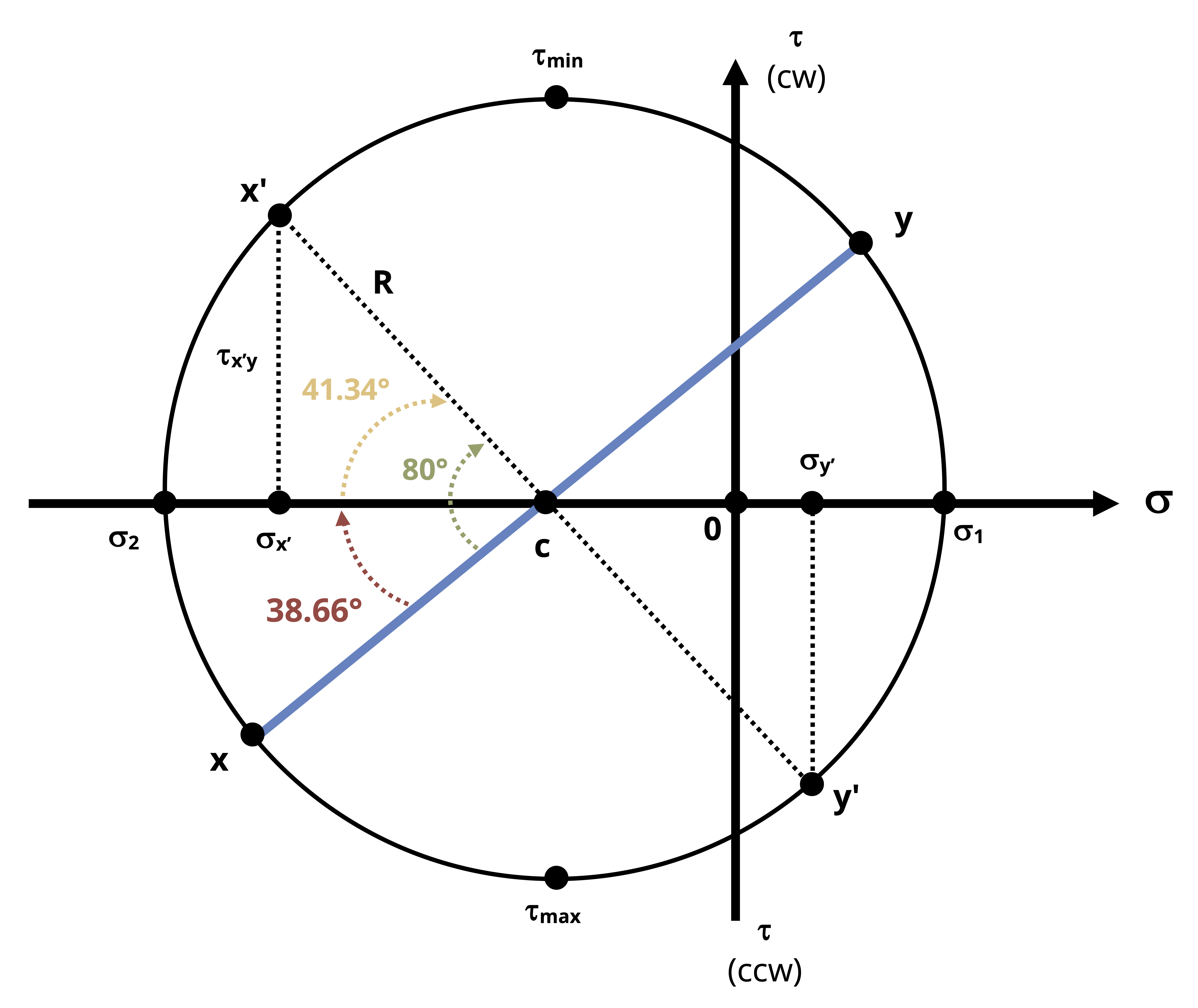

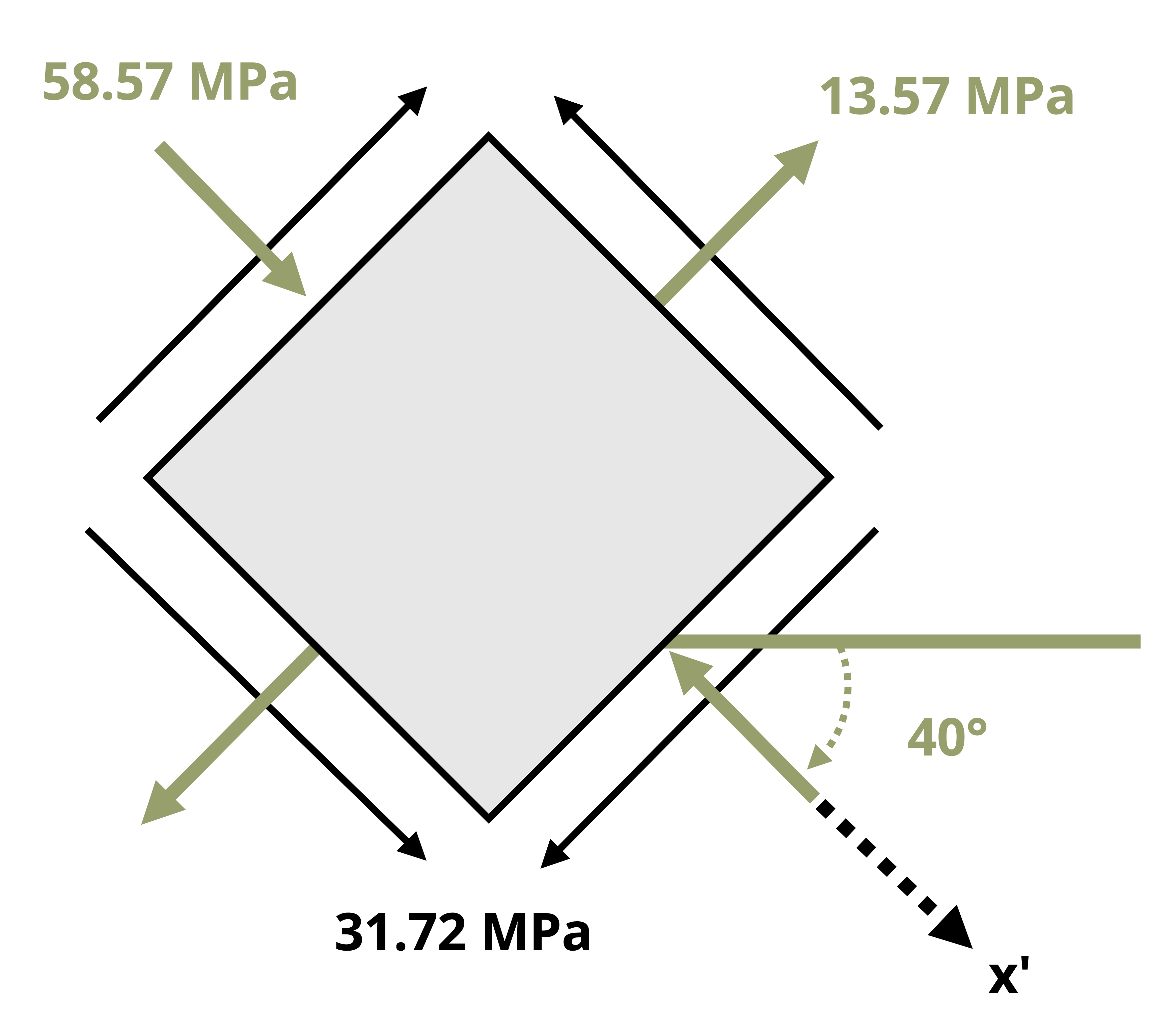

Rotations around the circle represent twice the actual amount of rotation between planes. Recall that rotations counterclockwise from the x point are positive angles and rotations clockwise from the x point are negative angles.

So the angle between the principal plane and the x point on the circle is 2θp. Determine this angle by applying right-triangle trigonometry principles to the same right triangle used to find the radius.

\[ \tan (2 \theta_p)=\frac{\tau_{x y}}{\sigma_x-C} \]Figure 12.16 shows that in this case the 2𝜃p angle has a counterclockwise rotation from the reference x-axis to the principal axis. Therefore if we were to draw the stress element rotated counterclockwise to 𝜃p, 𝜎1 would be drawn on the x’-face and 𝜎2 would be drawn on the y’-face.

The angle to the plane of max/min in-plane shear stress, θs, can be found in a similar manner. Visual inspection shows that 2θs will be the complement of 2θp. Recalling the convention used to apply a sign to the shear stress coordinate, note that the angle from the reference x-axis to the negative side of the shear stress axis will correspond to the rotation that results in the maximum in-plane shear stress and vice versa.

Once these quantities are known, the use of the circle to perform stress transformations at arbitrary planes requires making similar trigonometric calculations.

Example 12.4 demonstrates the use of Mohr’s circle to find maximum and minimum stresses and to perform stress transformations.

12.5 Mohr’s Circle in 3D and Absolute Maximum Shear Stress

Click to expand

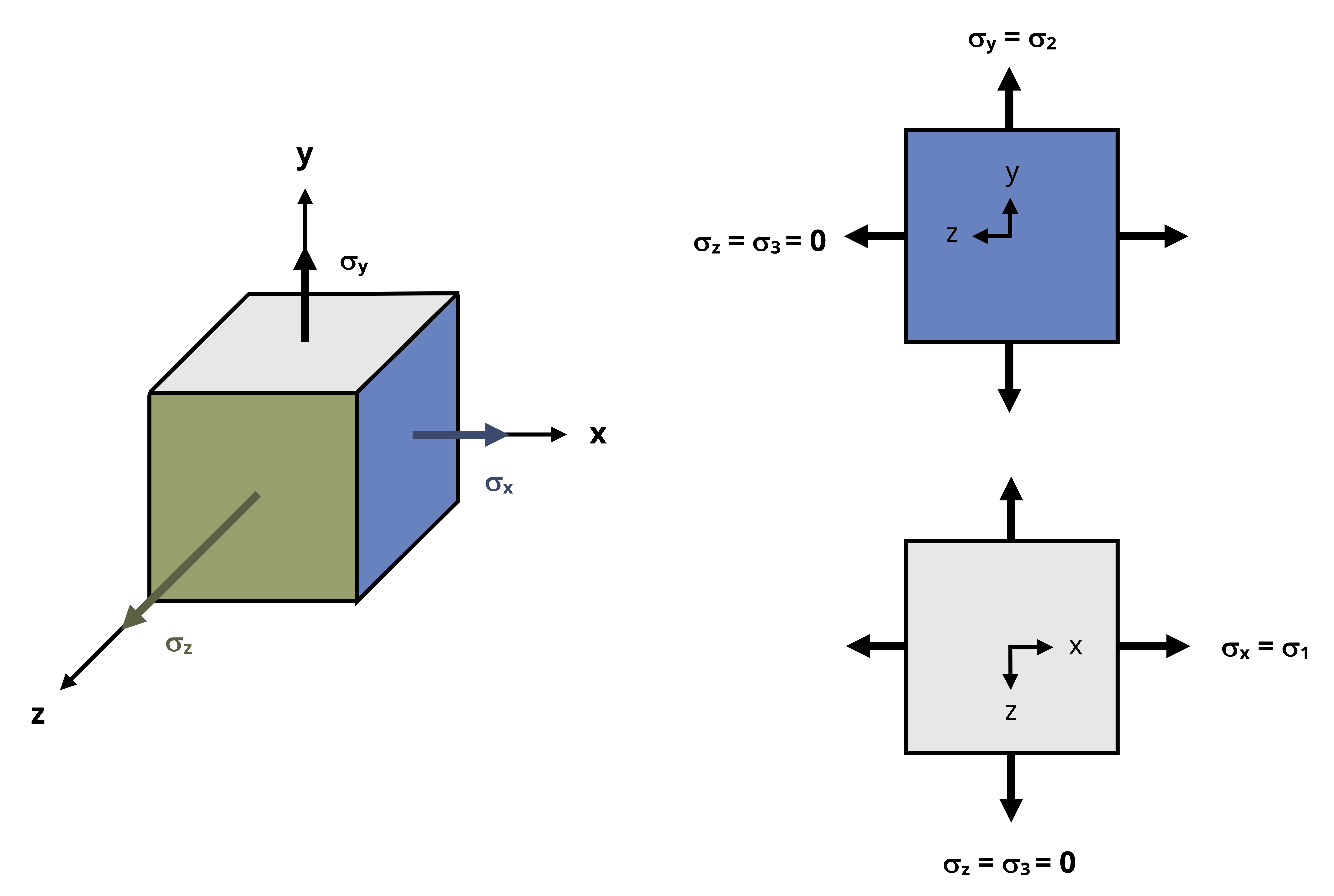

Many materials yield or fail in shear rather than normal stress, so knowing the absolute maximum shear stress the material is subjected to is important. The methods used in Section 12.3 and Section 12.4 provide the maximum in-plane shear stress that arises from rotations in the 2D plane (rotation around the z-axis in Figure 12.17). However, as discussed in Section 12.3, the actual maximum shear stress may result from an out-of-plane rotation (i.e., rotation around the x-axis or y-axis as in Figure 12.17). To account for this potential circumstance, we need to evaluate a 3D stress element despite still restricting analysis to 2D stress states.

For the sake of this discussion we’ll consider a reference stress state with stresses only in the x-y plane, though it could generally be any other 2D plane. To further simplify the discussion we’ll say that the stress element is already rotated around the z-axis to the principal stress state such that σx = σ1 and σy =σ2. The resulting 3D stress cube and representations of the x-z and y-z planes are shown in Figure 12.17. Given the plane stress restriction, 𝜏xz = 𝜏yz = 0, which means that the x-z and y-z planes are also at principal stress states. Designating the principal stress in the z direction to be σ3 means that the principal stresses in the x-z plane are σ2 and σ3 and that the principal stresses in the y-z plane are σ1 and σ3. For the reference stress state (plane stress), σ3 = 0 on all planes.

As the stress cube rotates around the x-axis, σz varies between 0 at 𝜃 = 0° and σ2 at 𝜃 = 90°. Meanwhile σy varies in the opposite way and σx remains unchanged. Similarly, as the stress cube rotates around the y-axis, σz varies between 0 at 𝜃 = 0° and σ1 at 𝜃 = 90°, whereas σx varies in the opposite way and σy remains unchanged.

We can draw Mohr’s circle for each of the three planes in Figure 12.17 on one plot. Just as the circle represents rotation of the stress element around the z-axis for stresses in the x-y plane, it represents rotation around the y-axis for the x-z plane and rotation around the x-axis for the y-z plane. We’ll consider three cases:

σ1 and σ2 are both positive.

σ1 and σ2 are both negative.

σ1 and σ2 have opposite signs.

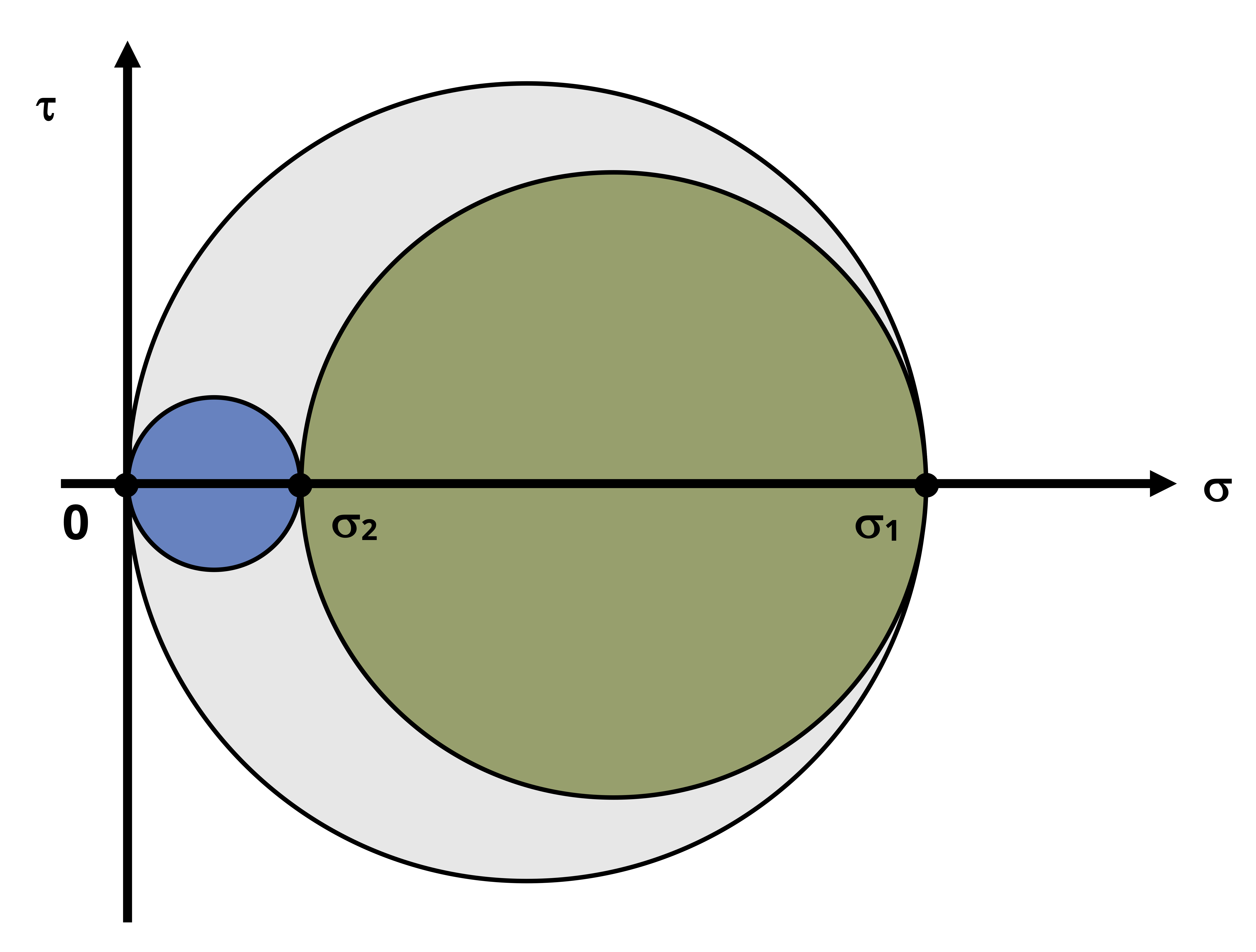

Case 1: σ1 and σ2 are both positive.

Referring to Figure 12.18, the larger inner circle is Mohr’s circle for the x-y plane, as evidenced by the maximum and minimum normal stresses on that circle, σ1 and σ2 respectively. The smaller inner circle is Mohr’s circle for the y-z plane, which has 0 and σ2 at the extremes. The largest circle is Mohr’s circle for the x-z plane, which has 0 and σ1 at the extremes. In this case the largest shear stress is given by the radius of the largest circle, which is \(\frac{\sigma_1}{2}\).

So in the case that σ1 and σ2 are both positive, the absolute maximum shear stress is

\[ \tau_{(\max )absolute}=\left|\frac{\sigma_1}{2}\right| \]

The absolute value is there since we know the maximum shear stress must be positive, given that the maximum and minimum shear stresses are negatives of each other.

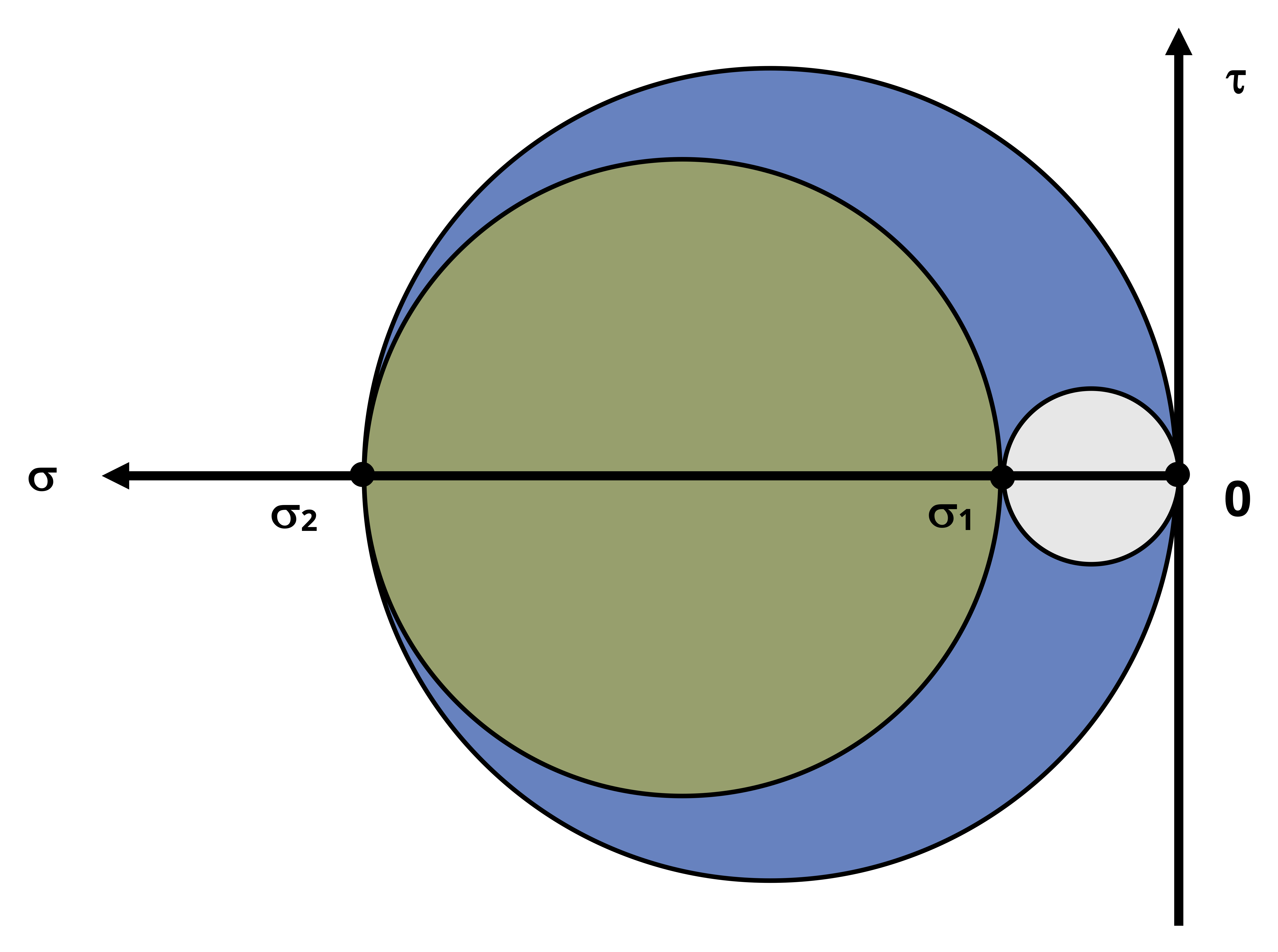

Case 2: σ1 and σ2 are both negative.

Referring to Figure 12.19, note that all the statements made in case 1 hold true here except that now the largest circle is that of the y-z plane for which the radius is \(\frac{\sigma_2}{2}\).

So in the case that σ1 and σ2 are both negative, the absolute max shear stress is

\[ \tau_{(\max )absolute}=\left|\frac{\sigma_2}{2}\right| \]

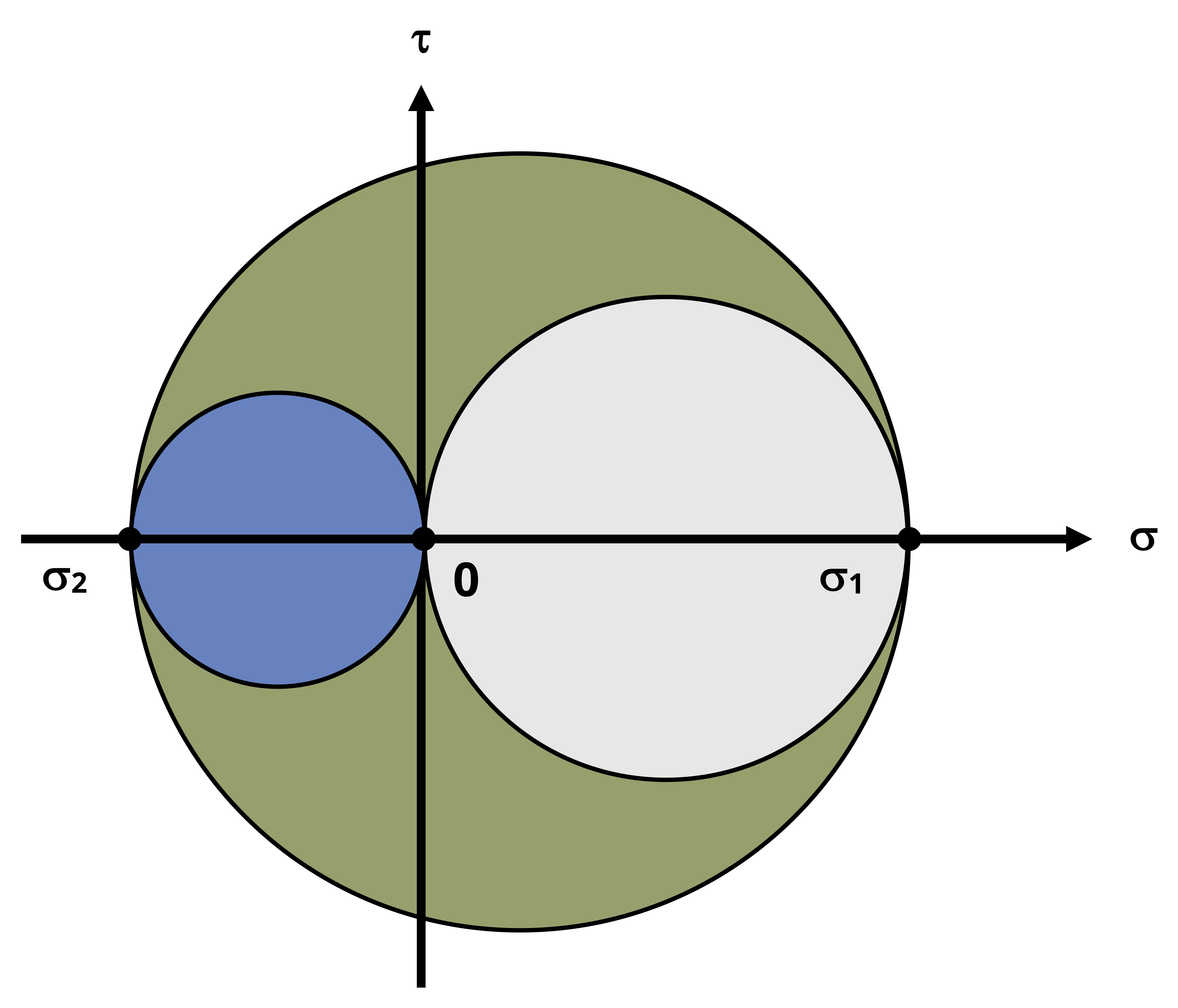

Case 3: σ1 and σ2 have opposite signs.

Referring to Figure 12.20, note that the Mohr’s circle for the x-y plane is the largest circle. This means that the absolute maximum shear stress and the maximum in-plane shear stress are the same.

So in the case that σ1 and σ2 are opposite in sign, the absolute maximum shear stress is

\[ \tau_{(\max )absolute}=\left|\frac{\sigma_1-\sigma_2}{2}\right| \]

More generally, given principal stresses σ1, σ2, and σ3 = 0, the absolute maximum shear stress can be determined from

\[ \boxed{\tau_{(\max)absolute}=\left|\frac{\sigma_{\max }-\sigma_{\min }}{2}\right|}\text{ ,} \tag{12.6}\]

𝜏(max)absolute = Absolute maximum shear stress [Pa, psi]

𝜎max = Maximum principal stress [Pa, psi]

𝜎min = Minimum principal stress [Pa, psi]

This works for any of the three cases:

Case 1: σmax = σ1, σmin = 0.

Case 2: σmax = 0, σmin = σ2.

Case 3: σmax = σ1, σmin = σ2.

Summary

Click to expand

References

Click to expand

Figures

All figures in this chapter were created by Kindred Grey in 2025 and released under a CC BY license, except for

- Figure 12.1: A pressurized duct is fabricated with welding in a helical pattern. Sneha Davison. 2024. CC BY-NC-SA.